306+

Patents & Intellectual

Property

60,000+ m²

Total Production

Area

10,000+ Units

Annual Production

Capacity

150,000+

Units in Global

Operation

605+

Professional Staff

Quality

Management

Environmental

Management

Occupational

Health Management

Energy

Management

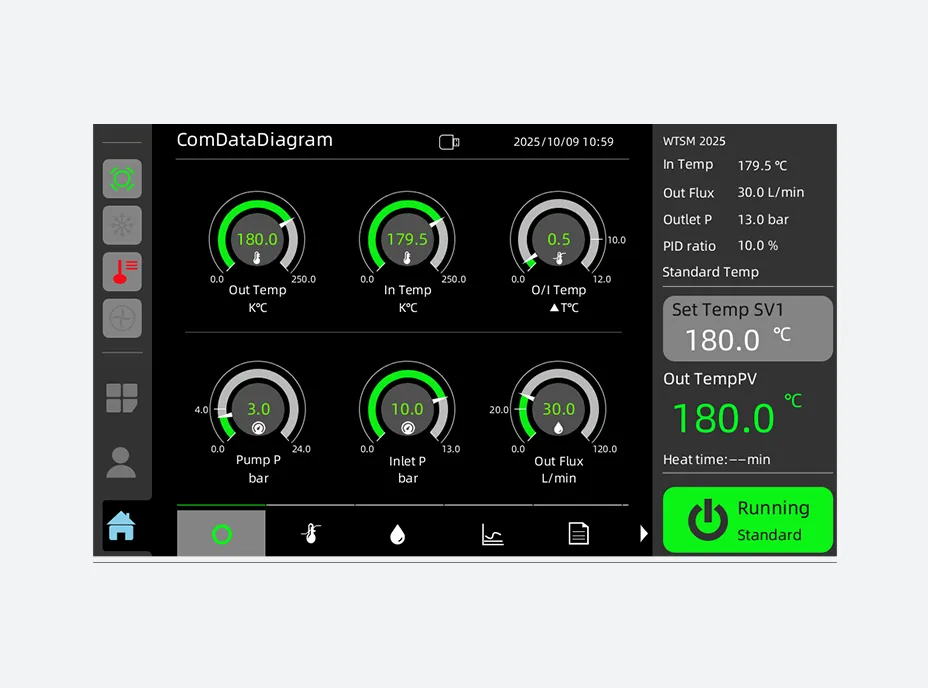

Temperature Control Unit

Engineered for Challenges in Temperature Contol of Various Industrial Product Molding Process

AODE Independently

developed core components

New innovation of industrial temperature control technology

Dual proportional Heating and cooling for quick temp adjusting delivers high-precision and stable temperature.

Without mechanical seals, eliminates oil or water leaks, reduce maintenance over time.

The non-immersed heater with water–electric separation helps prevent scale buildup, improves safety, and extends heater service life.

An Industrial Temperature

Control Equipment Manufacturer

Built on Strength and Scale

As one of the leading industrial temperature control equipment manufacturers, we leverage 22 years of expertise to deliver reliable solutions that set the standard for excellence.

As a key drafting unit for China's national mold temperature control standards, AODE not only follows industry best practices,but we also help create them.

Our systems are engineered for a service life of over 10 years. This market-proven durability ensures a superior return on investment and long-term peace of mind.

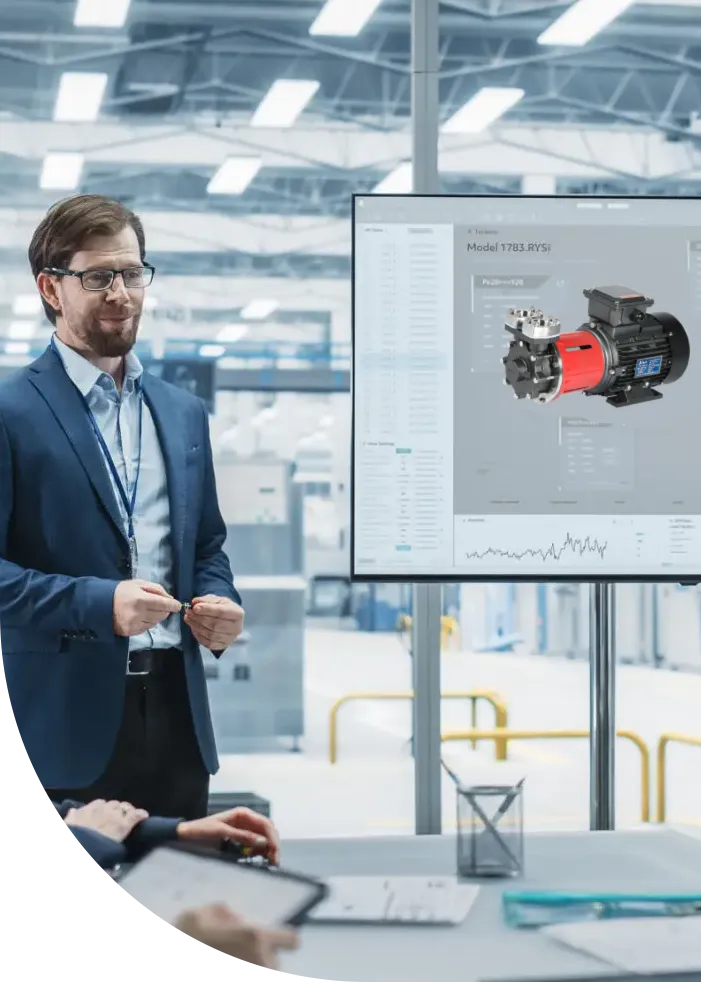

We are more than a supplier; we are a partner. We provide comprehensive technical training, sales support, and dedicated service to ensure our distributors succeed.

Patents & Intellectual

Property

Total Production

Area

Annual Production

Capacity

Units in Global

Operation

Professional Staff

As a world-classn idustrial temperature Unit manufacturer. We have a strong technical team and rich practical experience. Our expertise drives efficiency and quality improvements for the most critical applications.

Talk to us

Partner with a LeaderAs an AODE partner, you gain access to our complete ecosystem of industrial temperature control units, backed by our manufacturing scale, 22 years of expertise, and dedicated partner support. Let's capture new market opportunities together.