Industrial Water Chiller

AODE chiller series products mainly include air-cooled industrial chiller, water-cooled industrial chiller, air-cooled screw chiller, water-cooled screw chiller, water-cooled screw chiller, which are widely used in chemical industry, pharmaceuticals, energy storage, 5G materials, 3C communications, circuit boards, semiconductors, military industry, aerospace industry, rail transportation, optical lenses, sheet/board/circuit boards, and so on. Film material, dyeing and printing, rubber, injection moulding, packaging, drying, thermoforming of composite material, carbon fiber products and other industries.

The unit has complete protection functions, including power phase sequence, high and low pressure, motor overload, anti-freezing protection, etc.

Adopt international well-known brand compressor, high-efficient threaded tube heat exchanger.

Tank and water pipe material is stainless steel SUS304.

Refrigeration valves using Danfoss, Emerson and other well-known brands.

Electrical components using ABB, Siemens, Omron and other well-known brands.

Product Range

Industrial Chiller Units

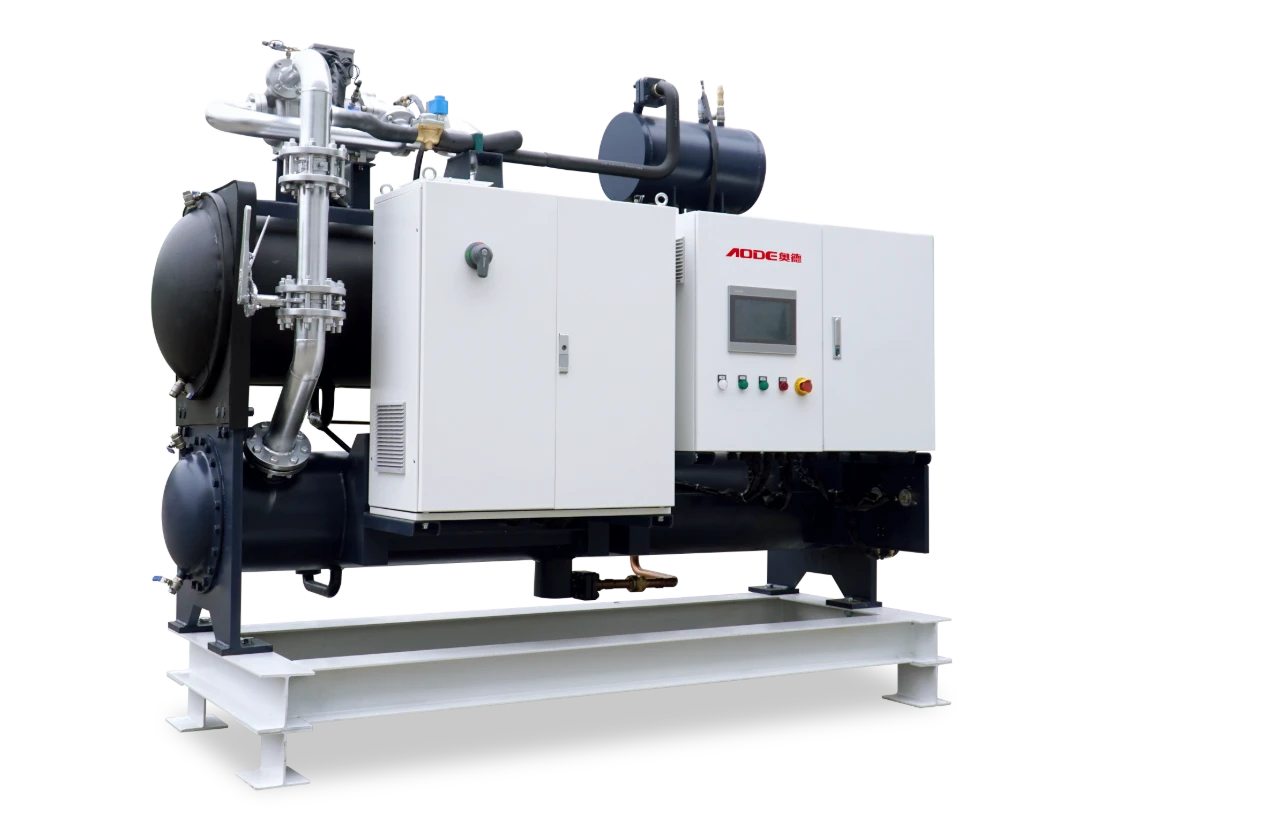

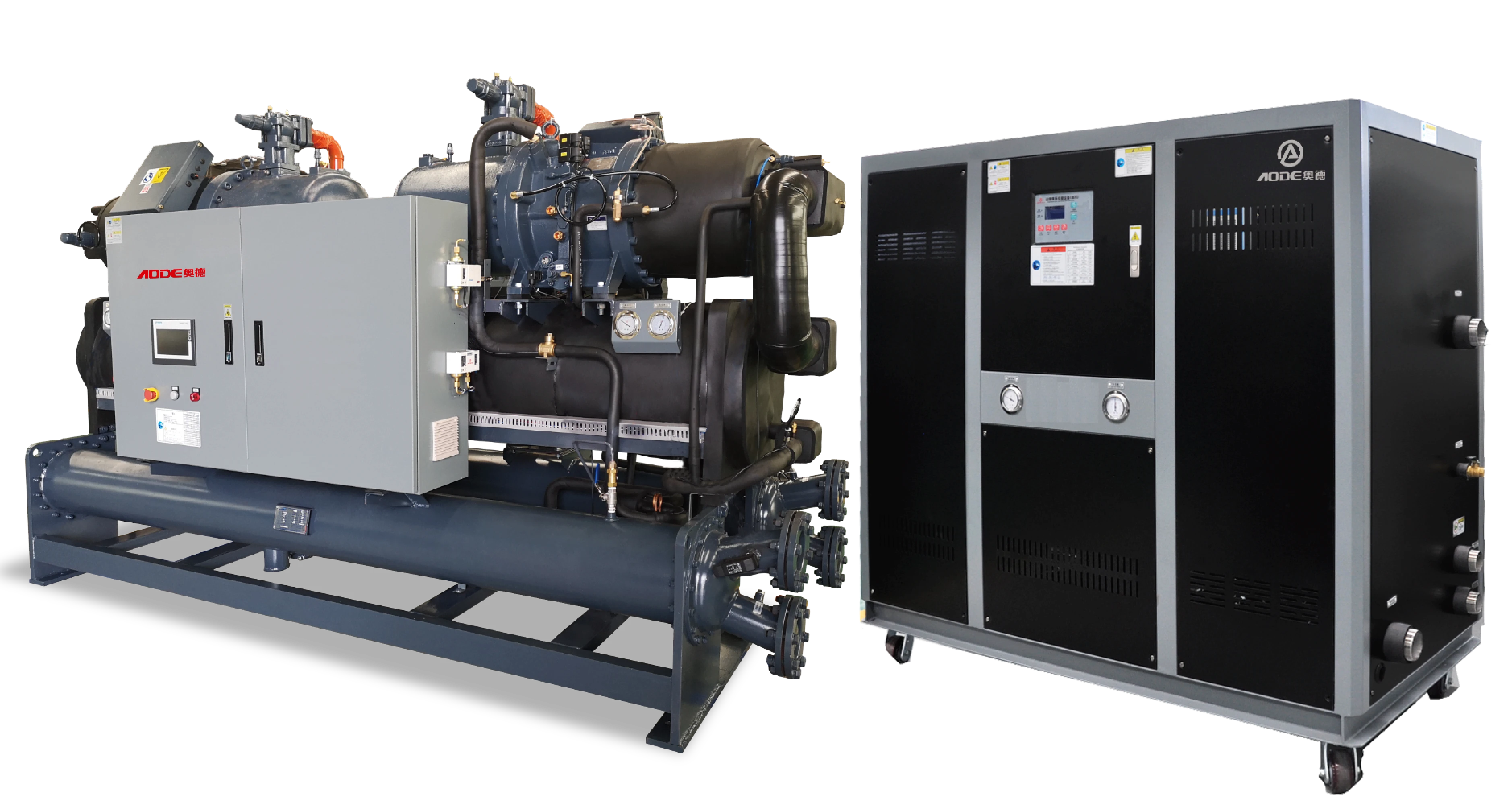

Water-Cooled Chiller

Higher system efficiency with a cooling tower/closed-loop condenser—designed for larger or continuous-duty plants seeking energy performance and acoustic comfort.

Air-Cooled Chiller

Packaged cooling without a cooling tower—ideal where installation simplicity, footprint, and quick deployment matter. Optimized condenser fans and controls support stable outlet temperatures and lower maintenance.

Application Solutions

Industrial Water Chiller System

-

Die Casting Industry

-

Injection Molding Industry

-

Film Industry

-

Composite Material Industry

-

Pharmaceuticals Industry

-

EV Components Test

-

Rubber Industry

-

Semiconductors

Provides reliable cooling to oil/water circuits, hydraulic units, and peripherals to manage high thermal loads in aluminum, zinc, and magnesium die casting. Coordinated with temperature control units, the chiller helps reduce porosity and thermal shock while protecting tooling over long runs.

The industrial chiller supplies steady process water (or water–glycol) to maintain a tight inlet temperature to molds and auxiliary equipment. Paired with mould temperature controllers (MTC/TCU), it absorbs peak heat at start-up and stabilizes cycle time and surface quality.

Delivers constant supply temperature to dies, calendar rolls, and cooling tanks, minimizing thickness variation and edge instability. For continuous lines, water-cooled chillers offer superior energy performance; air-cooled units suit compact, cell-based retrofits.

Supplies controlled cooling to presses, molds, and post-cure fixtures to manage ramp/soak profiles and extract heat uniformly from large tools. When paired with temperature controllers, the chiller promotes dimensional stability and surface quality while shortening turnaround between cycles.

Ensures consistent cooling for reactors, jacketed vessels, and packaging lines while supporting documentation and audit needs. Stable outlet temperature, alarms, and trend logs help maintain product quality and compliance.

Supplies tightly controlled chilled water (or water–glycol) to battery pack/inverter/drive-system test benches and environmental chambers. Stable setpoints reduce thermal drift in sensors and power electronics; optional alarms, trending, and DCS connectivity improve safety and traceability during endurance and thermal-cycle tests.

Delivers consistent cooling for internal mixers, calenders, extrusion lines, and molding presses—controlling roll and tooling temperatures to prevent scorch, improve dimensional stability, and enhance surface finish. Integrated with mould temperature controllers, the chiller balances heat removal across zones for repeatable curing profiles.

Provides low-fluctuation cooling for packaging/molding tools, process chambers, and test equipment where temperature stability and clean loops are critical. Communication options enable coordination with MTC/TCU for repeatable ramp/soak profiles and batch records.

FAQs

Industrial Water Chiller System

Air-cooled vs. water-cooled—how should we choose?

Choose by utilities, energy goals, noise limits, and footprint. Air-cooled units install fast and need no cooling tower; water-cooled units pair with a tower/closed loop for higher system efficiency and lower noise in continuous duty.

What information do you need to size an industrial chiller?

Heat load (kW), target supply/return temperatures, required flow/pressure, medium (water or water–glycol), ambient conditions, utilities (power/water), layout, and any compliance needs.

Can one chiller serve multiple machines or lines?

Yes—use a buffer tank/manifold with balanced branches, isolation and check valves, and flow control; coordinate setpoints and alarms via MTC/TCU or DCS/SCADA.

Contact Us

Get Your Temperature Control Solution

Tell us about your process, and our engineers will size the right mould temperature controller.

Share basic details and we'll return a tailored proposal and timeline within one business day.