Temperature Control Solution For Die Casting

AODE temperature control solution for die casting is mainly used in magnesium alloy, aluminum alloy, zinc alloy and copper alloy, which are applied in automobile parts, communication parts, electronic components, household appliances parts, furniture parts, power tools, aerospace, high-speed rail and so on.

High Integrity Die Casting Processes | One-Stop Solutions

Mold Temperature Control Units

Oil TCU for Die Casting

This oil temperature control unit is specifically designed for Die casting. Single or dual loop is optional to realize partition control. Preheat/cool, keep mold heat balance. Prolong die life. Improve productivity.

Water TCU for Die Casting

High-temperature water temperature controllers up to 200℃, water as the heat transfer medium to reduce operating costs. Magnetic circulation pump to ensure leak-proof operation and feature a comprehensive safety control design.

Jet Cooler for Die Casting

To cool the jetting tube with inner diameter≤ 2.5MM. Eliminate defects such as shrinkage cavities and thermal shrinkage, avoid localized overheating of the mold, prevent premature cracking or damage of the cavity and core due to high temperatures, and extend the mold life.

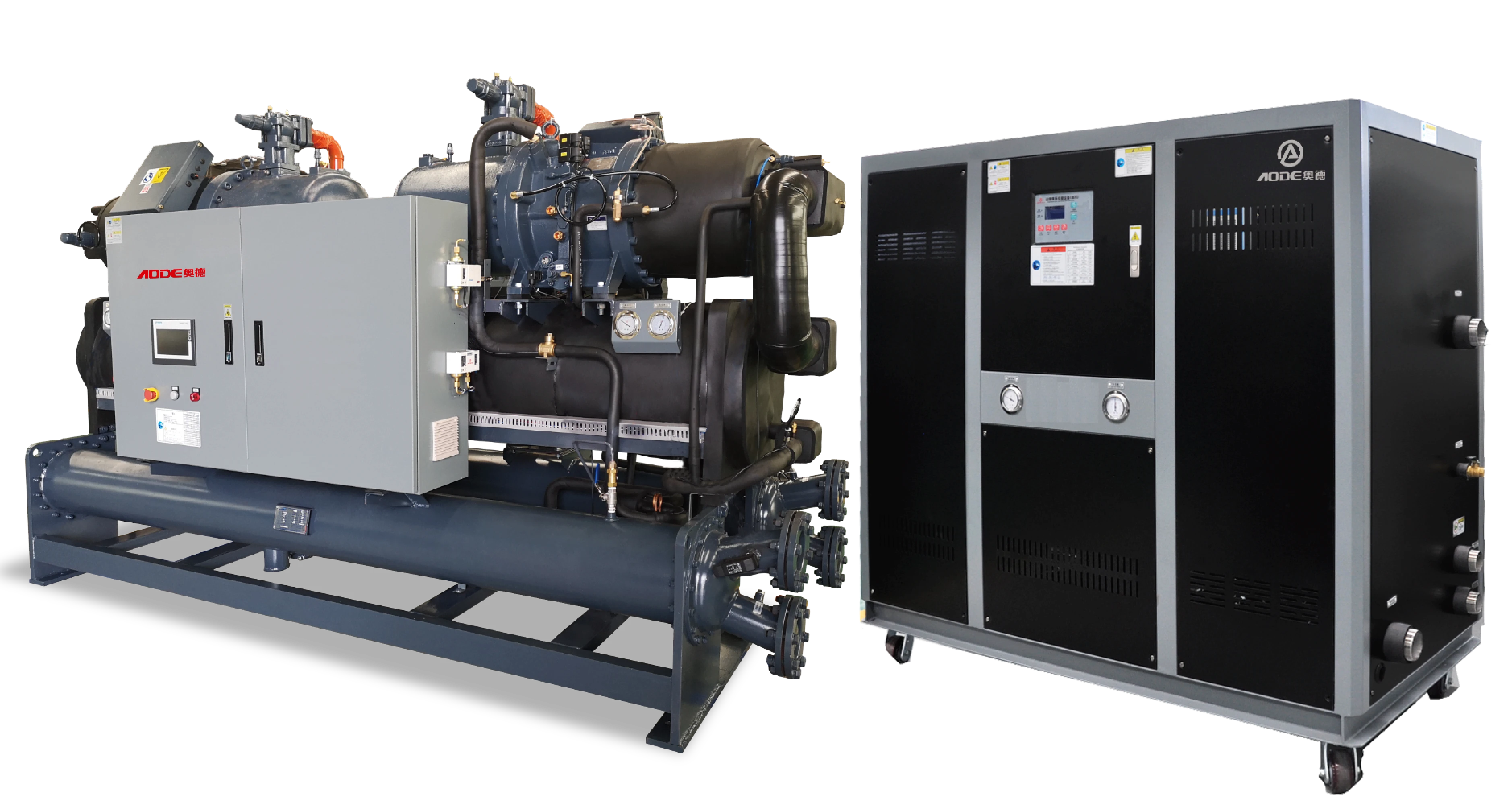

High Pressure Die Cooler

A reliable chilled-water source that feeds die circuits, peripherals, and TCUs. Maintains a steady supply temperature and coordinates with water/oil TCUs to balance overall thermal load.

Mold Cooling station for Die Casting

Achive accurate temperature control and mold heat balance by supplying cooling water to different zone of the mold. Improve cooling efficiency. This cooling station solve the whole mold cooling control.

Key Technology | Mold Temperature Control

Mould preheating technology

01

Precise and controllable die cooling technology

02

Cooling technology for hot joint of casting

03

Mould temperature on-line monitoring technology

04

Intelligent control technology of mold temperature

05

IIOT control technology

06

Closed loop control technique

07

Centralized heating and cooling temperature control scheme

08

Mold Temperature Controller Manufacturers

Which should I choose, a single-circuit or a dual-circuit die-casting oil temperature controller?

It depends on what product you are making and whether you have a moving mold and a fixed mold.

Is it safe to use high temperature and high pressure 200℃ water temperature controller?

It is very safe, with a complete safety protection design. Including protection with: pump reverse phase, water shortage, overheating, overloading, high pressure, pressure divergence, and flow divergence.

Contact Us

Get Your Temperature Control Solution

Tell us about your process, and our engineers will size the right mould temperature controller.

Share basic details and we'll return a tailored proposal and timeline within one business day.