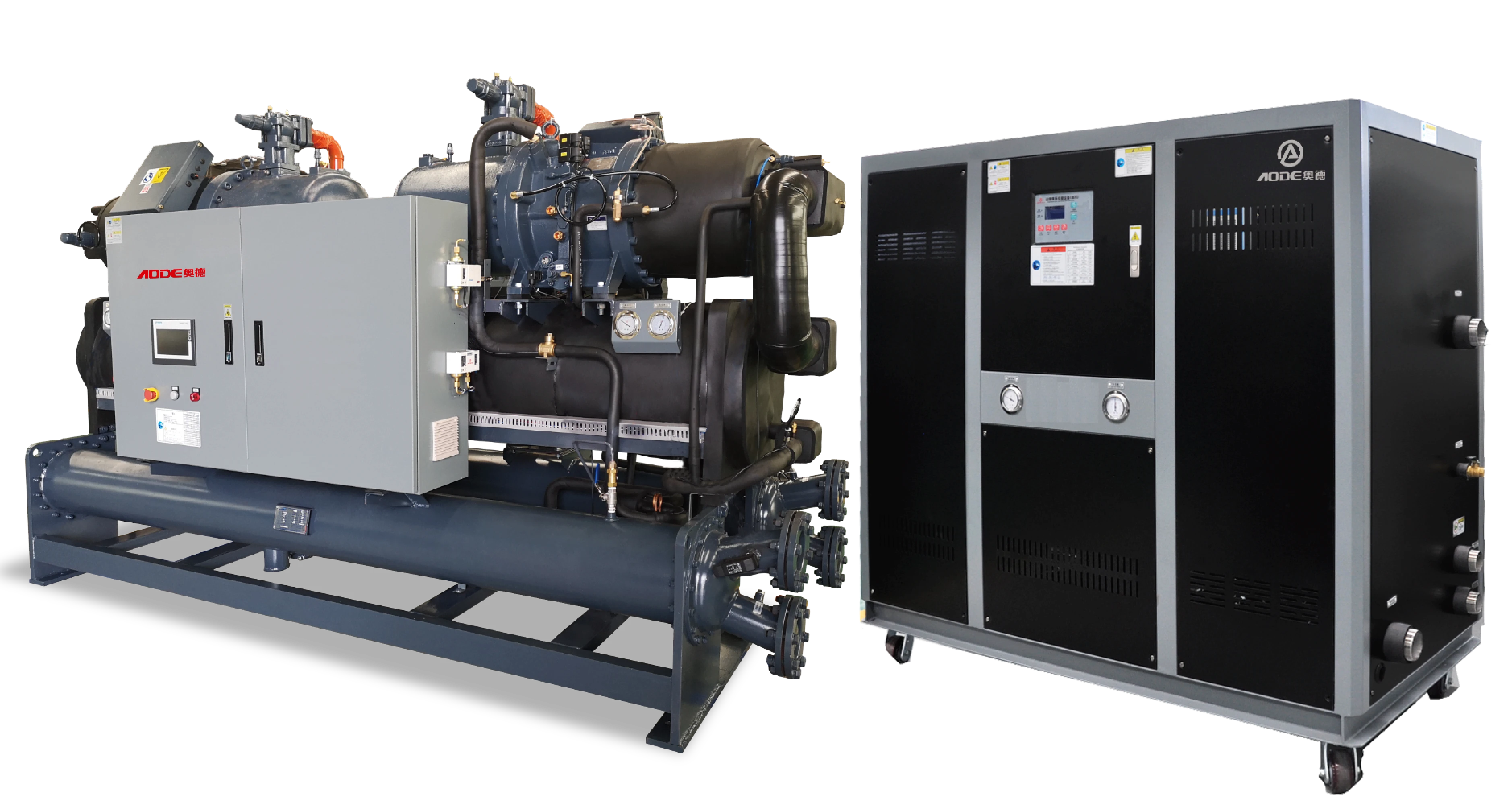

Engineered for Precision & Stable Temperature Control in Industry

Mould temperature machine series products mainly include oil temperature machine, water temperature machine, 200℃ high-temperature water machine, 320℃ die-casting mould temperature machine, rapid cooling and rapid heating high-gloss mould temperature machine, 400℃ ultra-high-temperature oil temperature machine, electrically heated organic heat carrier furnace, etc. They are widely used in the chemical industry, pharmaceuticals, new energy automobile integrated die-casting, energy storage, 5G materials, 3C communication circuit boards, semiconductors, the military industry, aerospace, rail transportation, auto parts die-casting, optical lens, sheet/plate/film dyeing and printing, rubber, injection moulding, packaging, drying, compound material thermoforming, carbon fibre products and other industries.

Return oil/water temperature display, Automatic exhaust.

Heating power switch, By-pass pressure release circuit.

Temperature control range;+45℃~400℃(oil) +45℃~180℃(water).

Control mode: imported microcomputer or PLC (optional).

Electric components: SIEMENS、Weidmuller, ABB, LS, OMRON.

Safety protection: fault display, easy repair and maintenance.

Explosion-proof,Blowing back oil/water (optional).

RS485 communication(optional).

Product

Temperature Control Units

Optics Precision Temperature Controller

Smart IoT with built-in sensors monitors flow, pressure and temperature, while real-time diagnostics for getting fine controlled.

Water Temperature Control Unit

Precise, steady control for mainstream molding—clean water loops, fast ramp/soak, and easy maintenance.

Oil Temperature Control Unit

Specialized mold temperature controller for die-casting industry with rapid heating and precise thermal stability.

Temperature Control Unit

The AODE TCU temperature control system utilizes the client's primary cooling/heating utilities to supply the secondary TCU system, which then precisely controls the process temperature, ensuring only one heat transfer medium circulates within the reactor jacket.

Rapid Cooling and Heating Mold Temperature Controller

Designed for high-precision molding, this unit rapidly heats and cools molds to eliminate defects like weld lines, improve surface finish, and shorten cycle times. Ideal for automotive lenses, high-gloss parts, and electronics housings.

Solutions | Case Study

Discover Our Industrial Temperature Controller

-

Die Casting Industry

-

Injection Molding Industry

-

Film Industry

-

Composite Material Industry

-

Pharmaceuticals Industry

-

EV Components Test

-

Rubber Industry

-

Semiconductors

Stabilizes preheat, fill, and solidification; reduces porosity and thermal shock. Use Oil MTC / High-Temp Water MTC; TCU for multi-zone dies.

Tight setpoints and fast changeovers improve cycle time and surface finish. Choose Water MTC; High-Flow for large molds.

Keeps die/roll temperatures uniform to minimize thickness variation; TCU enables zone balancing.

Follows cure ramp/soak profiles with high-flow uniformity on large tools; Oil MTC or High-Temp Water MTC recommended.

Clean loops with low fluctuation and batch traceability via DCS; use Water MTC with clean options.

Stable control for benches/chambers reduces thermal drift; logs improve safety and traceability.

High-flow, zoned control prevents scorch and improves dimensional stability on mixers/calenders/presses.

Very low fluctuation and clean circulation for packaging tools; Optical-grade Water MTC or high-precision configs with TCU.

Frequently Asked Questions

Can the same controller handle both water and oil?

Models are tailored to media. We’ll recommend a water or hot-oil MTC based on your mold, temperature, and cycle requirements.

How do you minimize leakage risk?

What's the typical accuracy?

Contact Us

Get Your Temperature Control Solution

Tell us about your process, and our engineers will size the right mould temperature controller.

Share basic details and we'll return a tailored proposal and timeline within one business day.