Industrial Heater Thermostat

wafers, photoresists, cmp polishing materials, wet electronics chemicals, precursors for wafer body encapsulation materials, M0 sources, etc.), semiconductor equipment (including cleaners, oxidation ovens, lithography, PVD/PECVD, probe tables, inspection equipment, sorting machines, data centre liquid-cooled CDU distribution units, etc.).

Intelligent PID algorithm, support for segmented temperature control, automatic algorithms, fuzzy control and other functions, high accuracy of temperature control.

Refrigerant system using hot gas bypass temperature control, dynamic adjustment of the system load, energy saving and high efficiency.

The product series covers multiple temperature zones, can match the semiconductor industry with different processes.

Special optimisation of the structure, low vibration, low noise.

With Automatic purge function.

Optimised for coolant piping process, low risk of leakage.

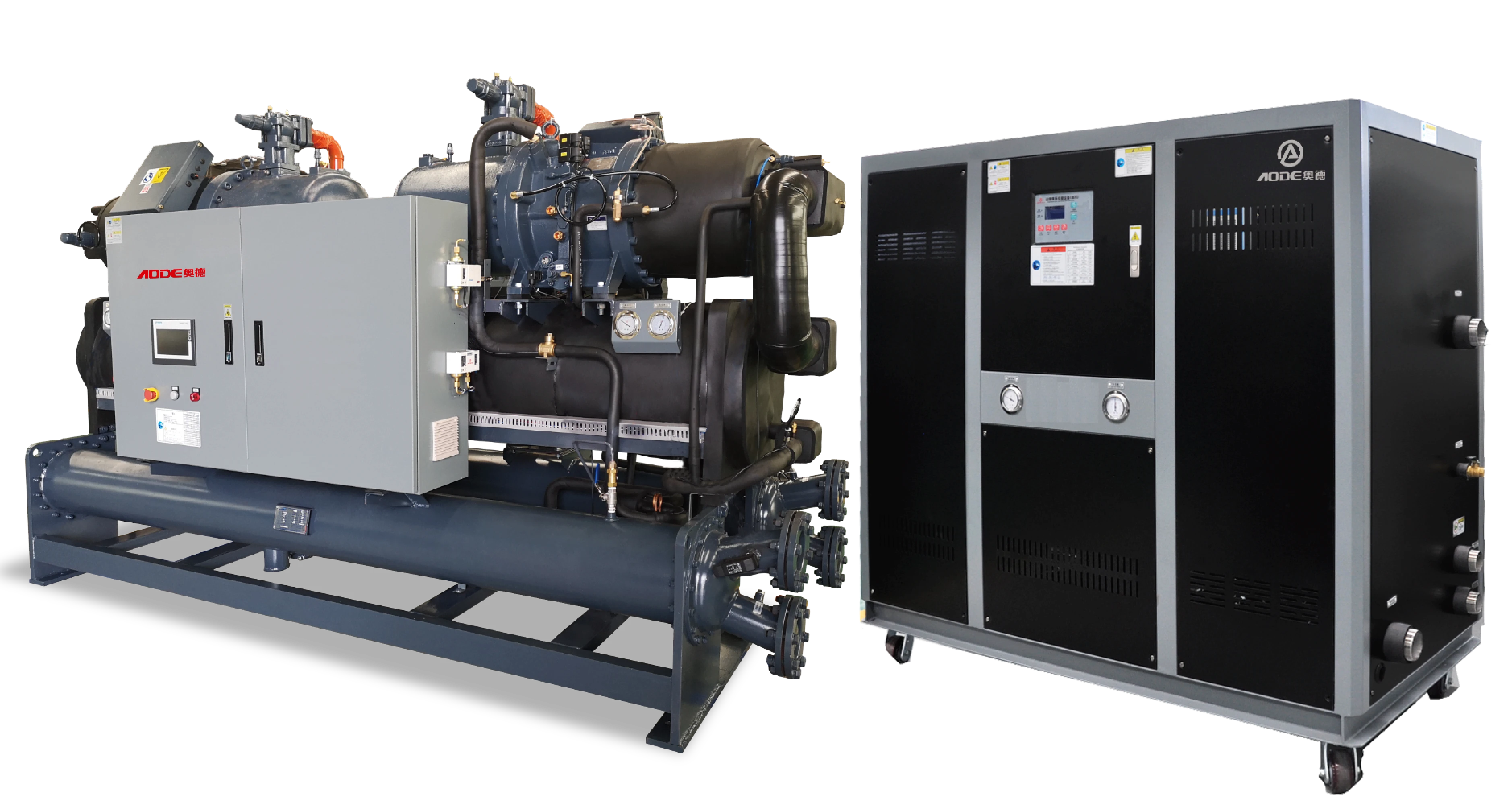

Product Range

Industrial Digital Thermostat

ACT Integrated Cooling-Heating Series

The ACT series is an advanced integrated temperature control system designed for precision industrial applications. Combining both cooling and heating functions in one compact unit, it provides stable and efficient temperature management for various industrial processes. Featuring intelligent control, high reliability, and energy-efficient operation, this all-in-one solution simplifies installation while ensuring optimal performance in demanding environments.

ACH High-Low Temperature Series

The ACH series delivers precise temperature control for both heating and cooling applications. Designed with reliable performance and simple operation, these units provide stable thermal management across a wide temperature range. Ideal for various industrial processes requiring accurate temperature regulation.

From High to Low, Smart Choice

Fluid Temperature Control System Integration

-

Pharmaceuticals Industry

-

EV Components Test

-

Semiconductors

Gentle ramps and stable holding on jacketed vessels, reactors, and packaging lines; documentation and alarm logic support compliance and audit readiness.

Precise chilled-water (or water-glycol) for battery pack, inverter, and drive-system benches or environmental chambers; stable setpoints reduce thermal drift in sensors and power electronics, with logs for safety and traceability.

Low-fluctuation control for packaging molds, process chambers, and test tools, with clean loops and batch records; integrates with DCS/SCADA for alarms, trends, and traceability.

Frequently Asked Questions

Industrial Thermostat Controller

When should I choose the integrated air chiller vs. the fluid temperature control unit?

Use the integrated air chiller as a packaged cooling source (no tower) and pair it with tools or MTC/TCU; choose the fluid temperature control unit when you need precise heating–cooling coordination, multi-zone logic, or oil-based control.

Can both connect to our plant system?

Yes—selected models offer communication options and gateways for DCS/SCADA to coordinate setpoints, alarms, trends, and reports.

What process data should we prepare?

Heat load, target supply/return temperatures, flow/pressure, medium, utilities, and layout.

Contact Us

Get Your Temperature Control Solution

Tell us about your process, and our engineers will size the right mould temperature controller.

Share basic details and we'll return a tailored proposal and timeline within one business day.