Leadership & Reliability

R&D Recognized National High-Tech Enterprise

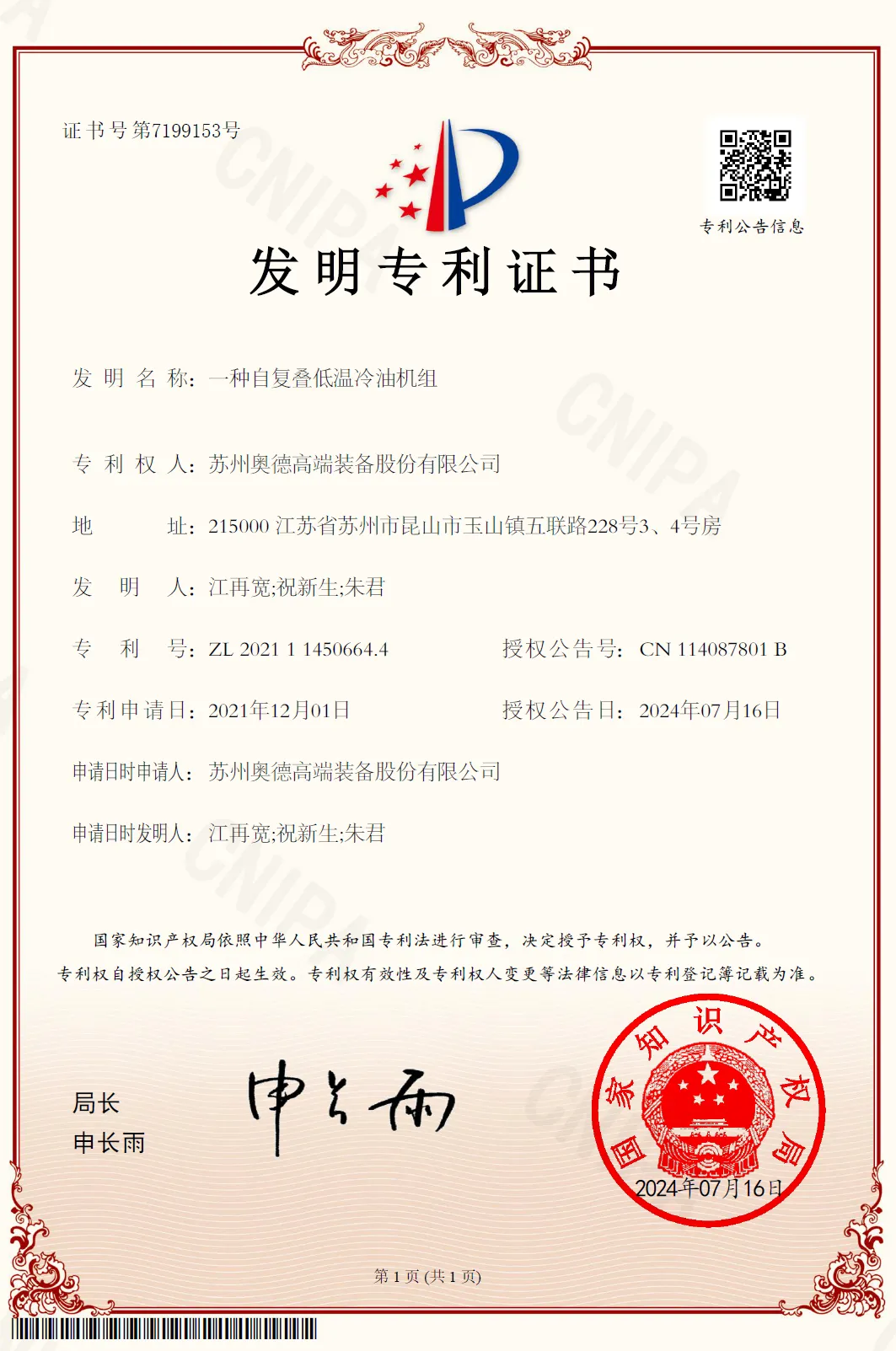

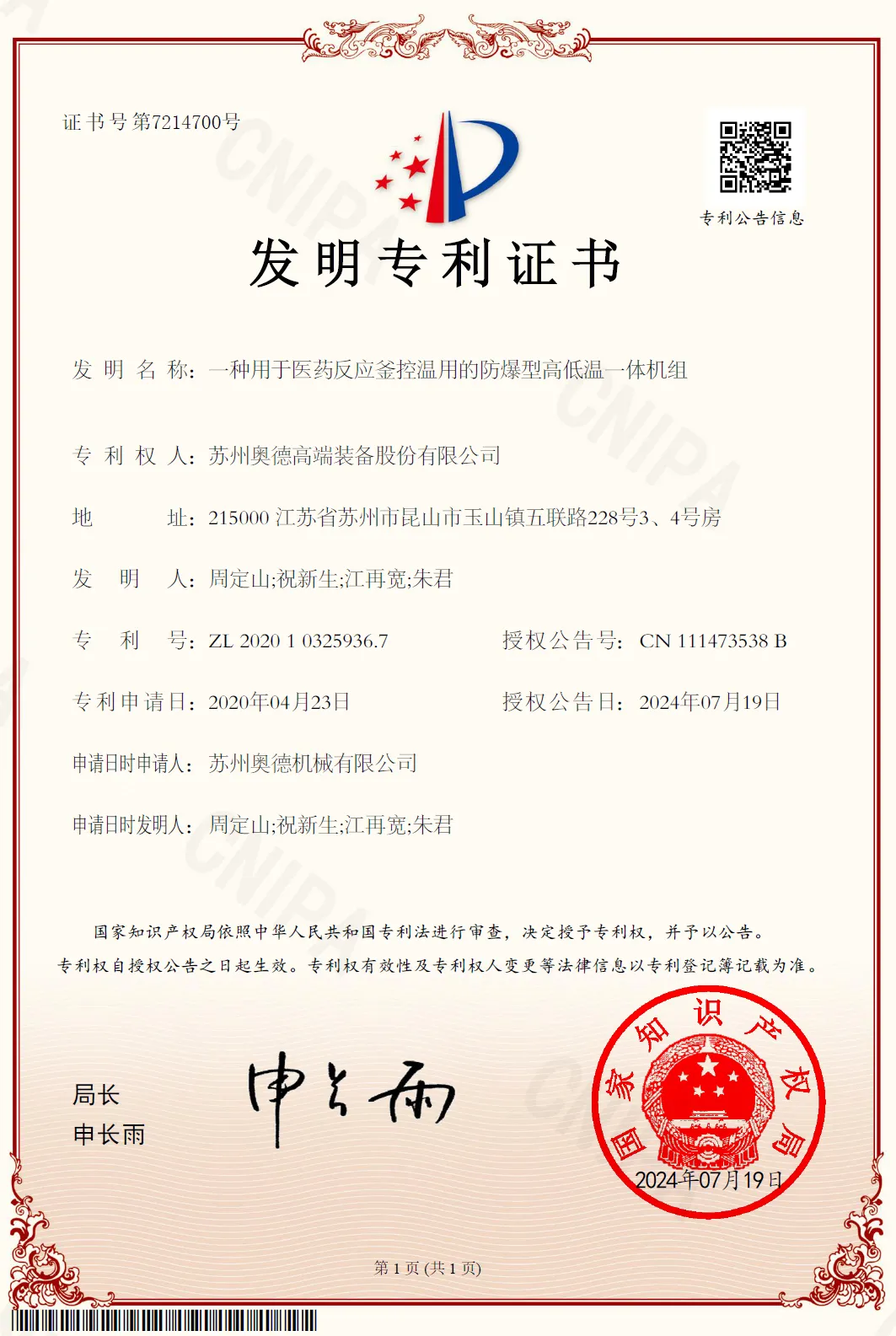

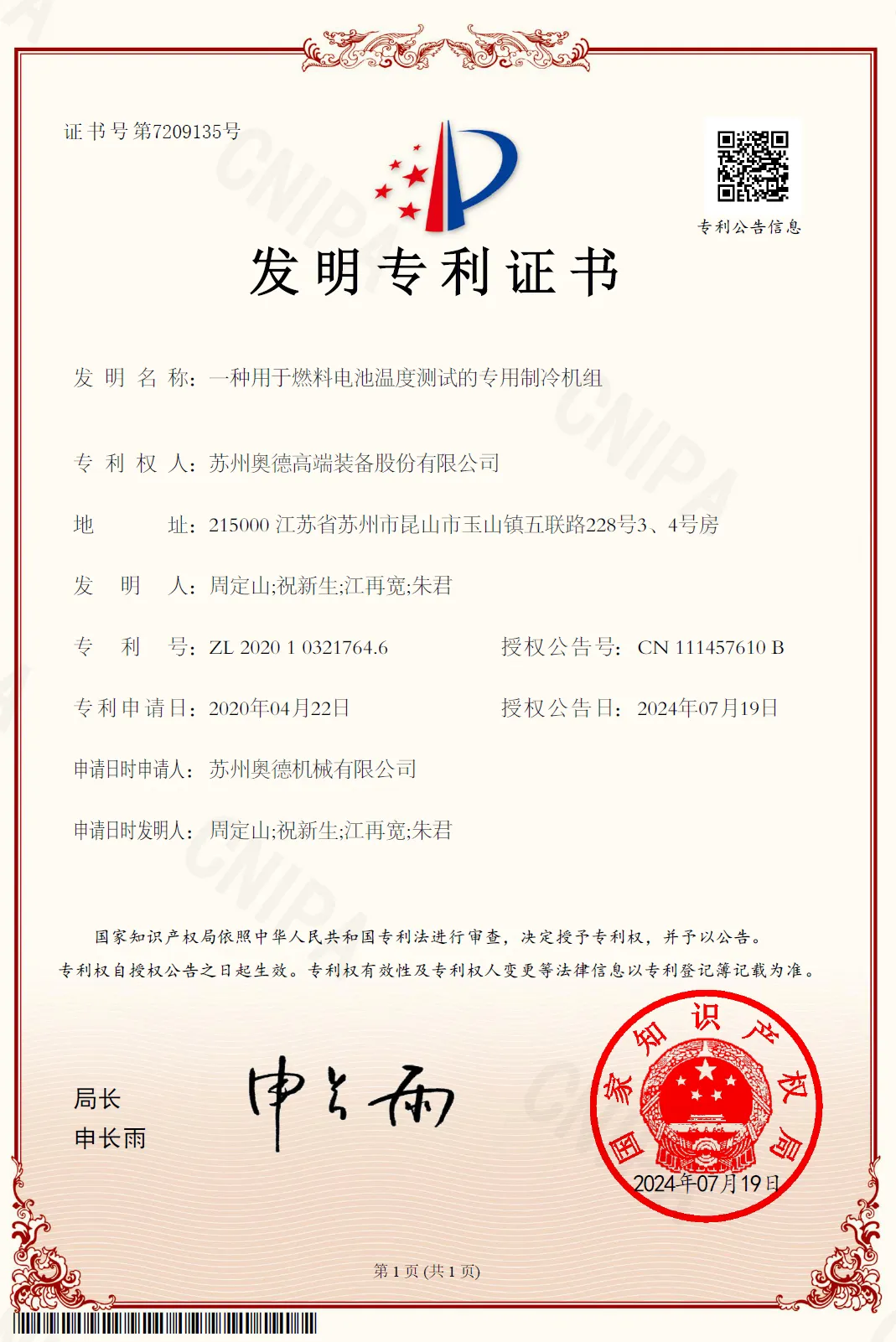

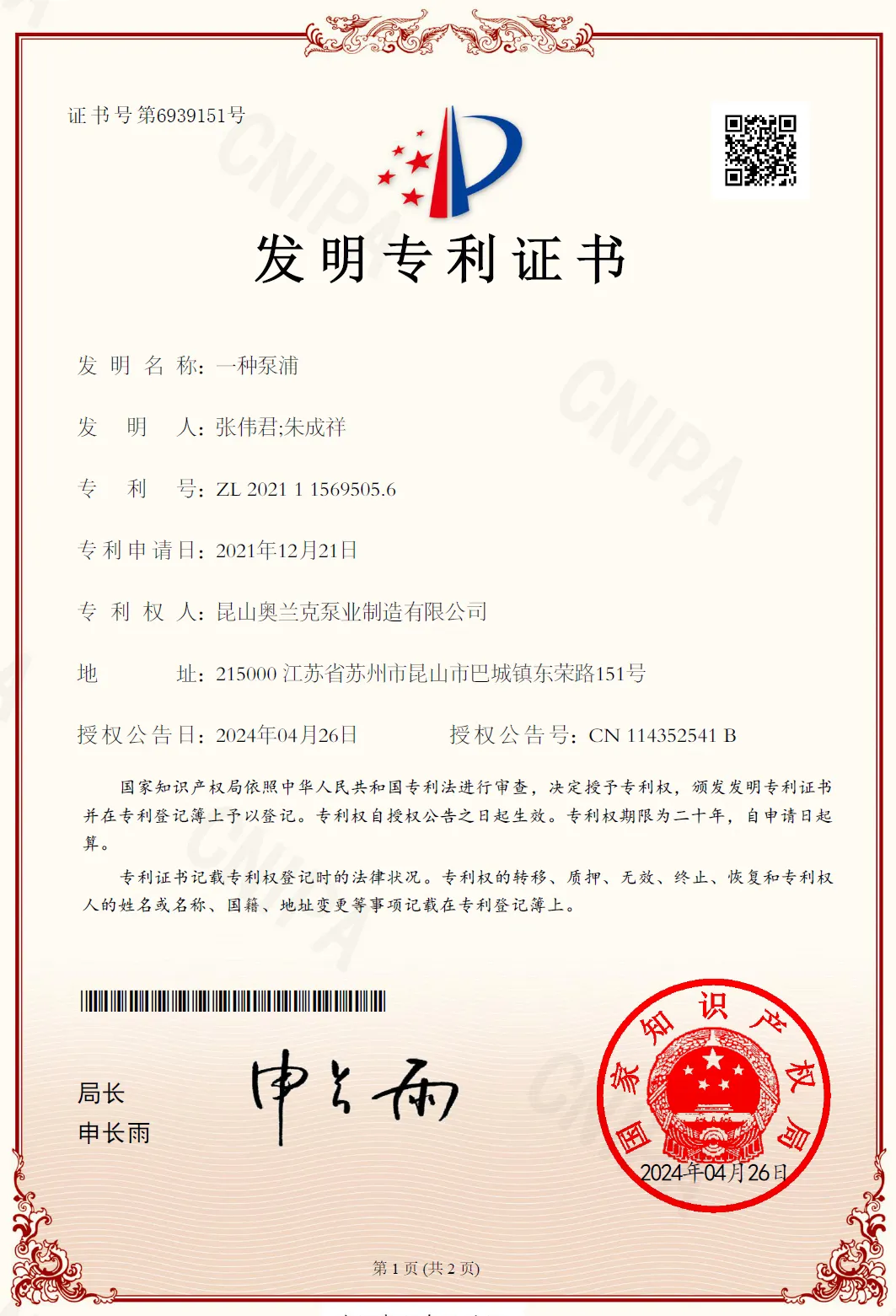

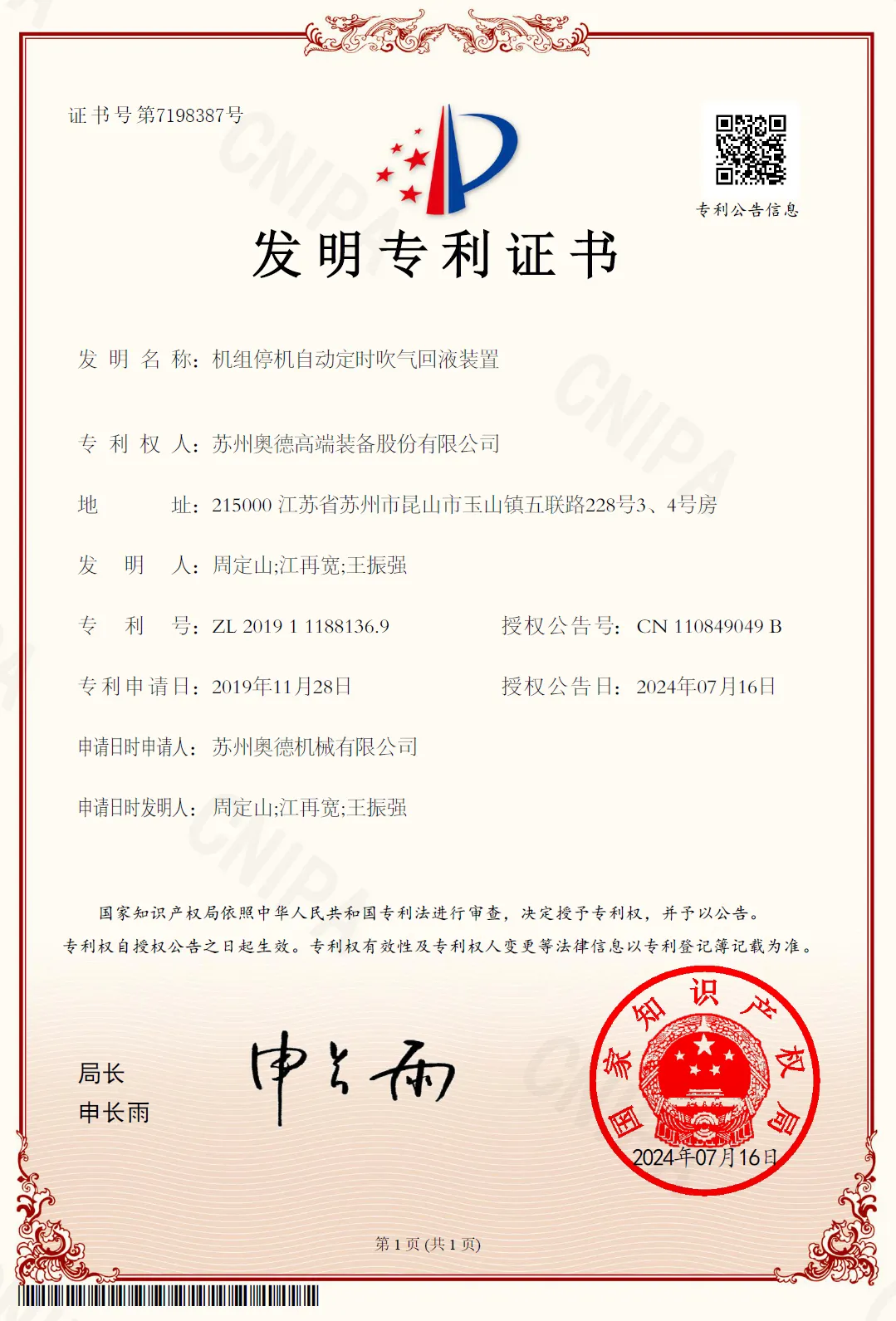

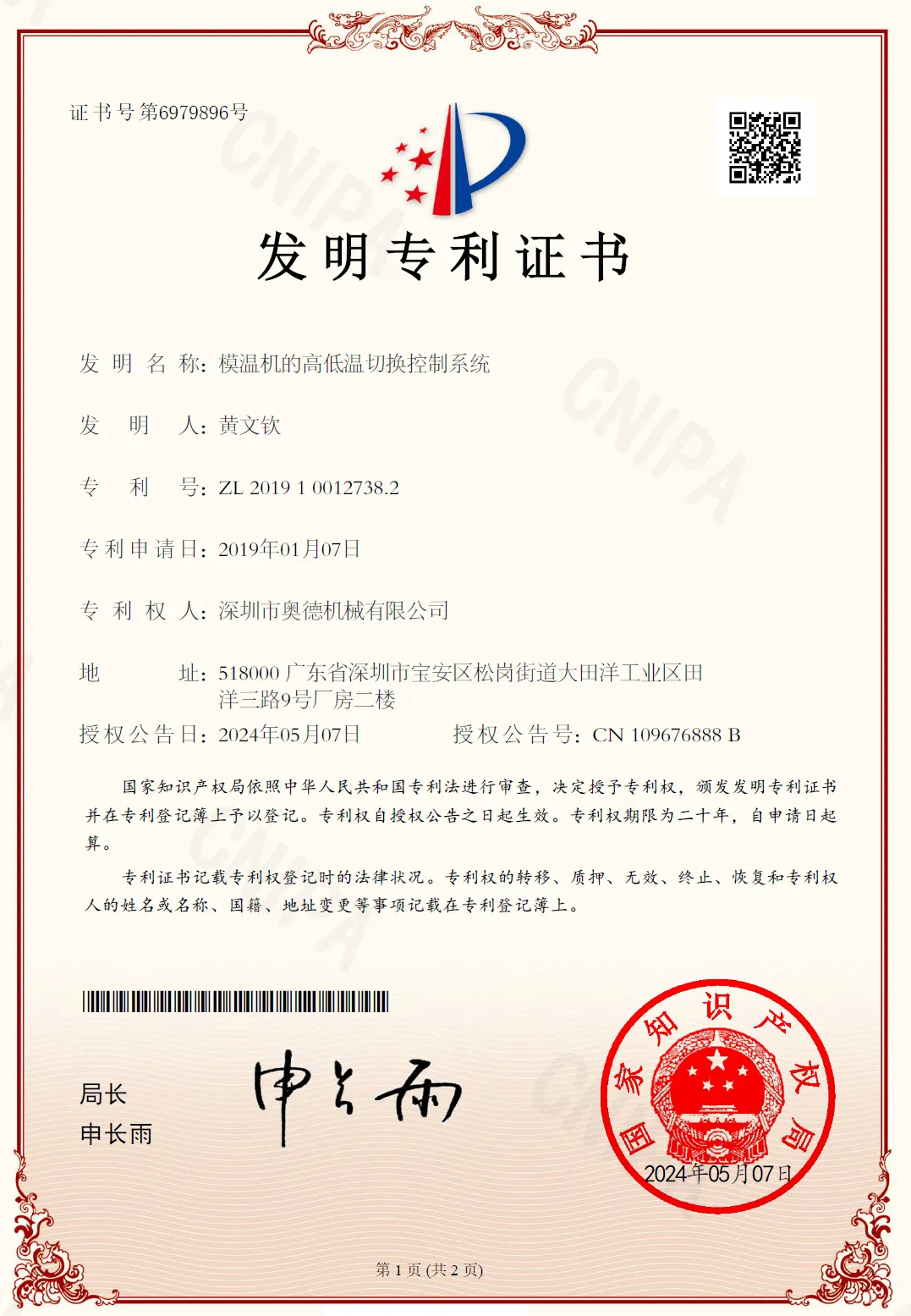

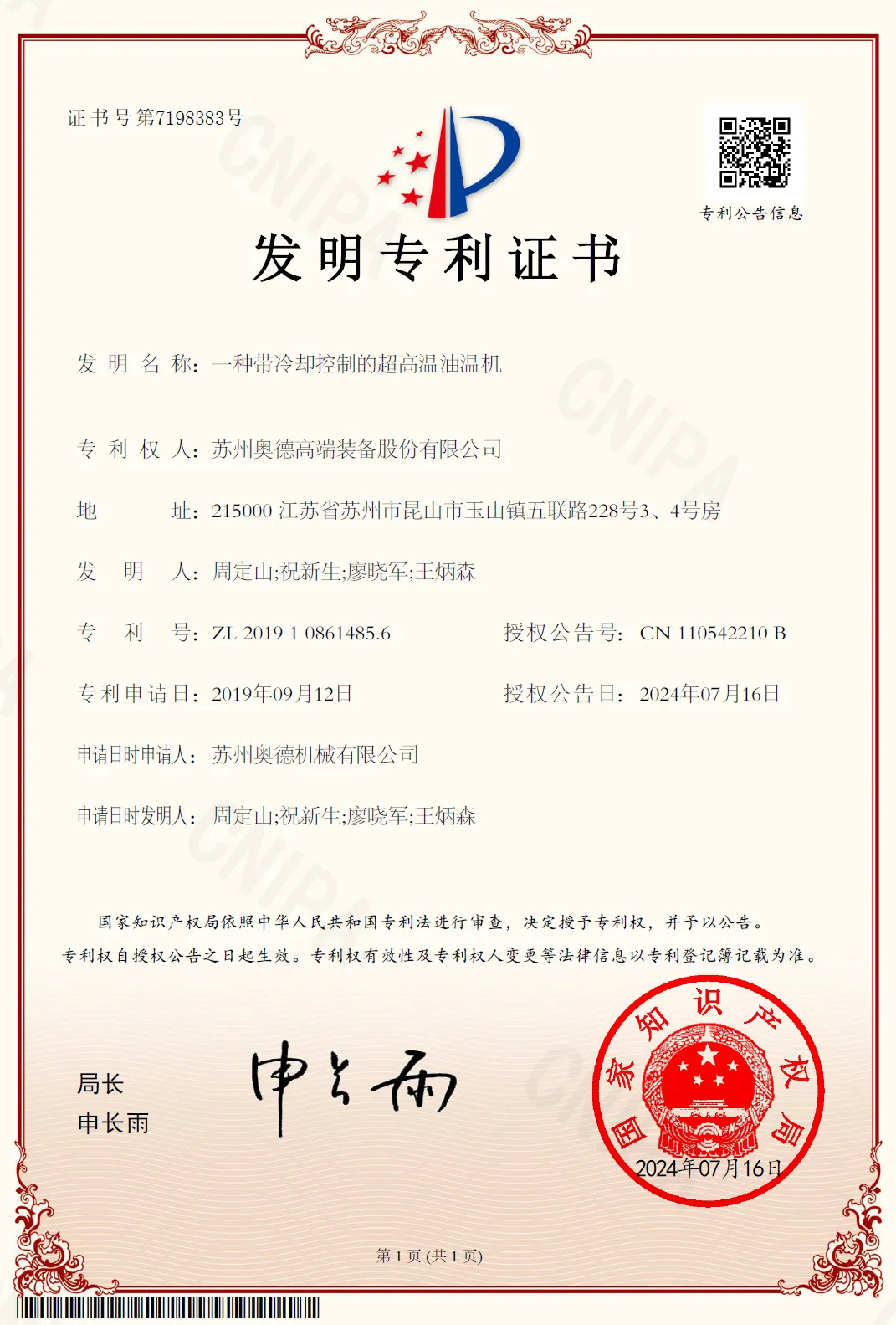

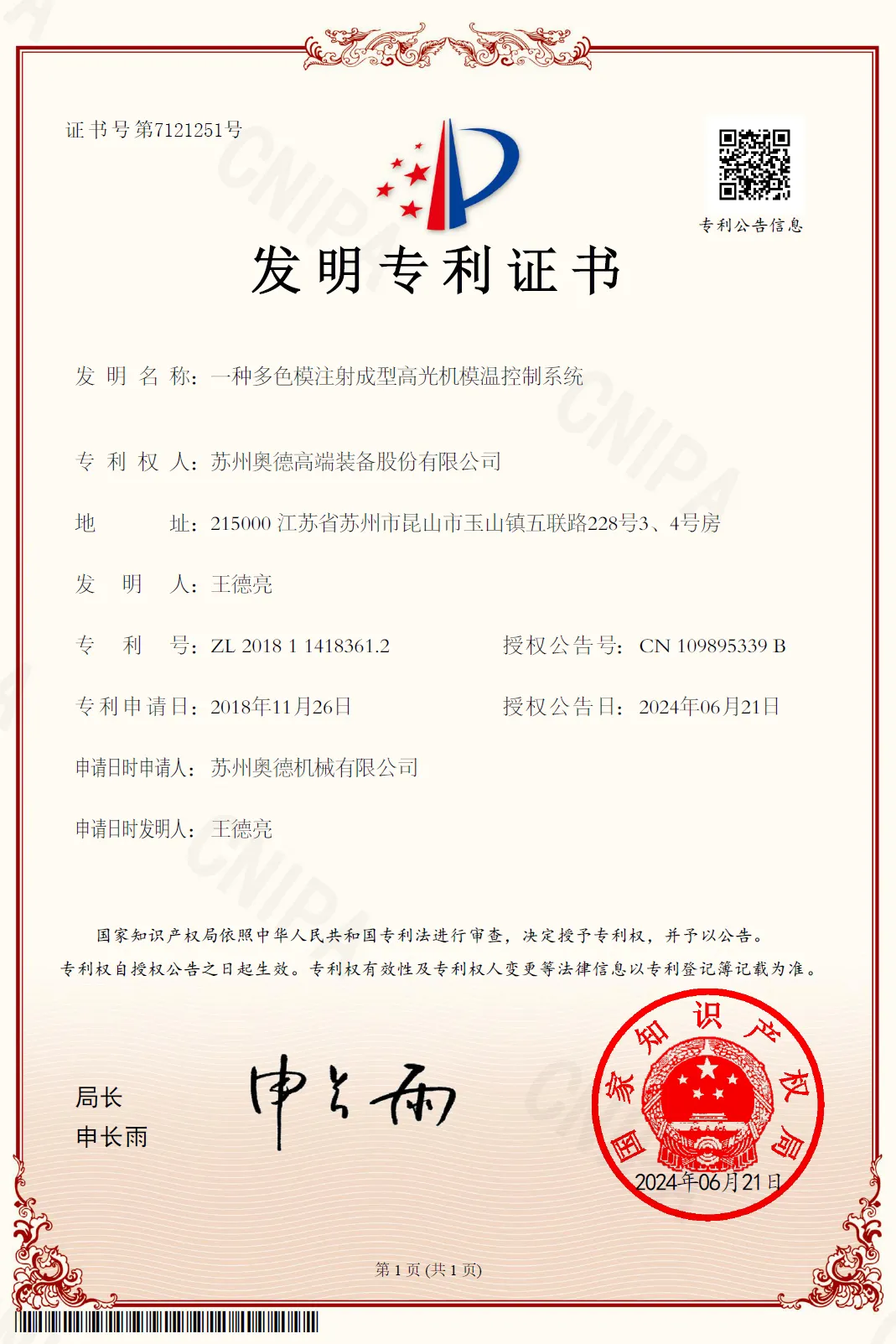

306+

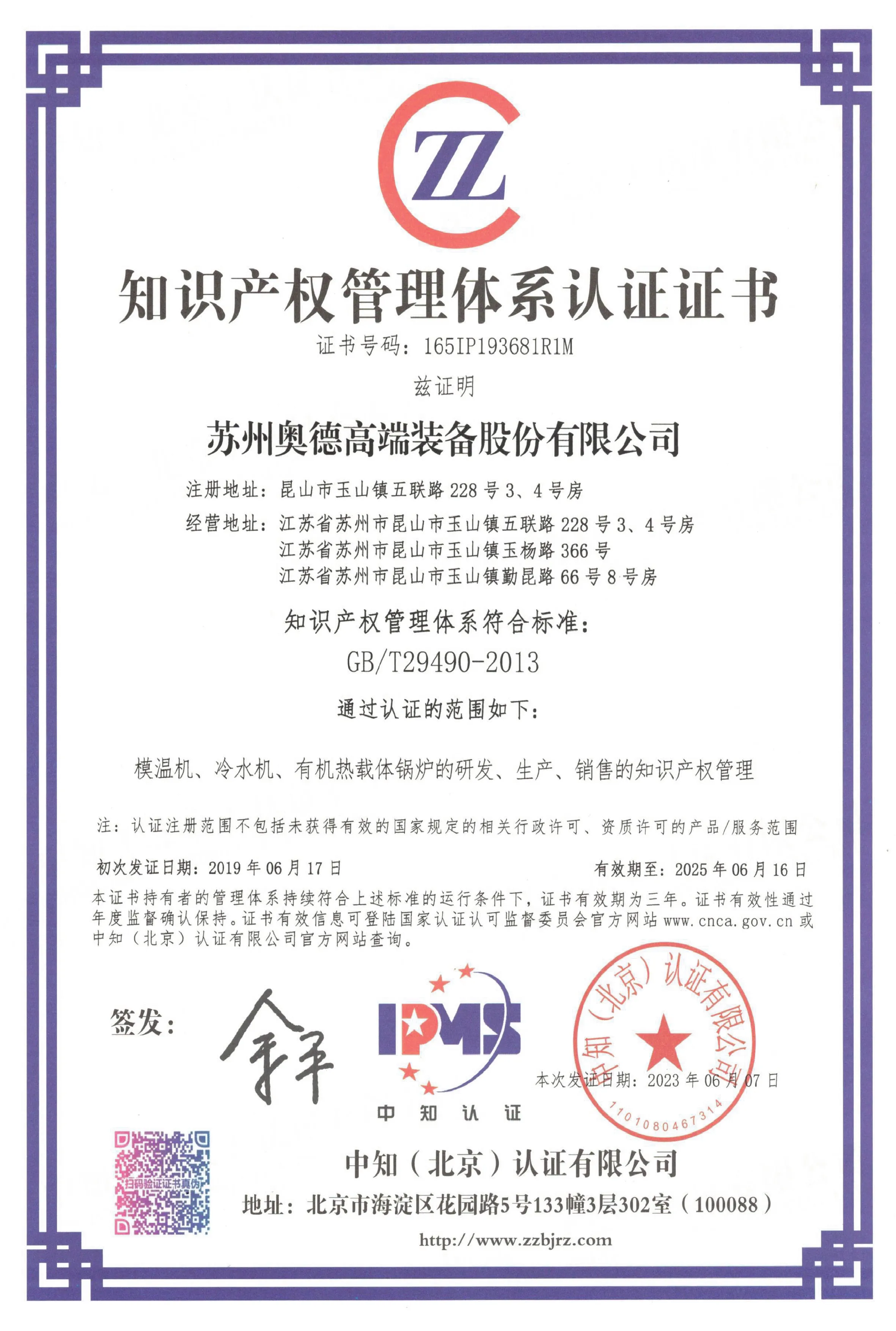

Patents & Intellectual Property

60,000+m²

Intelligent Industrial Park

83+

Core Research Personnel

22+

Years of Experience

2

Research Centers

8

Manufacturing Base

Aode R&D Center

(Now relocated in Shanghai)

Innovation in Reliability

Patents

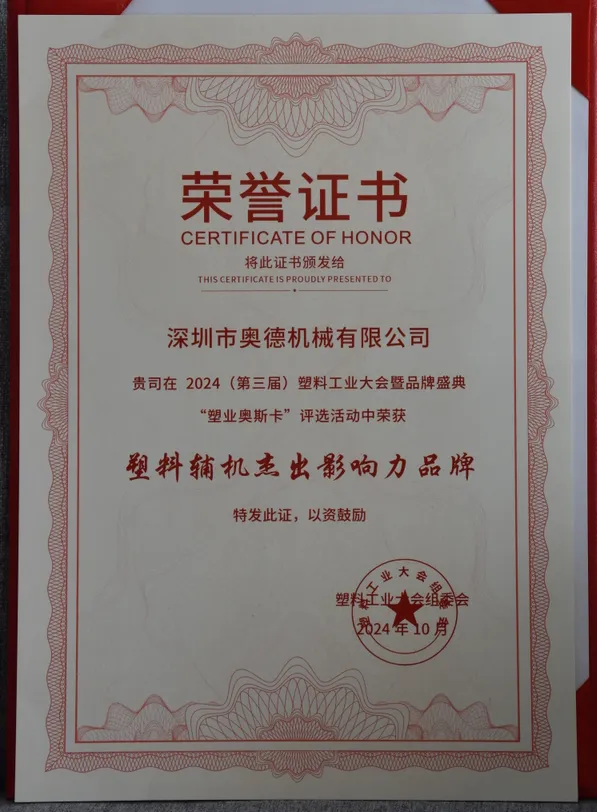

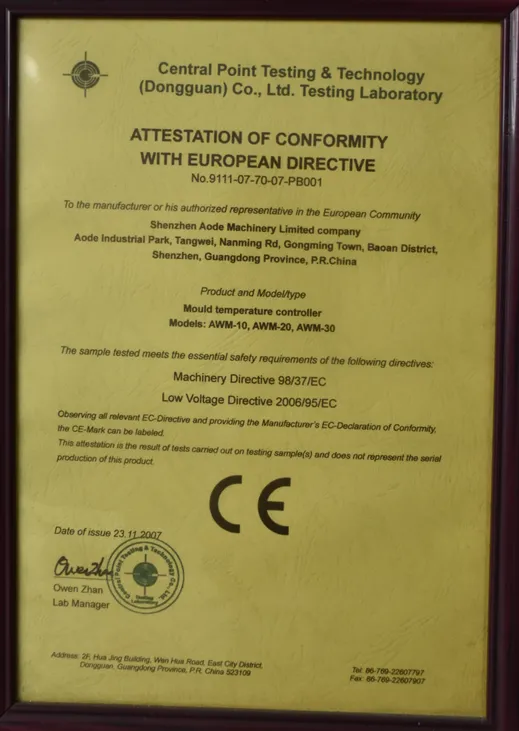

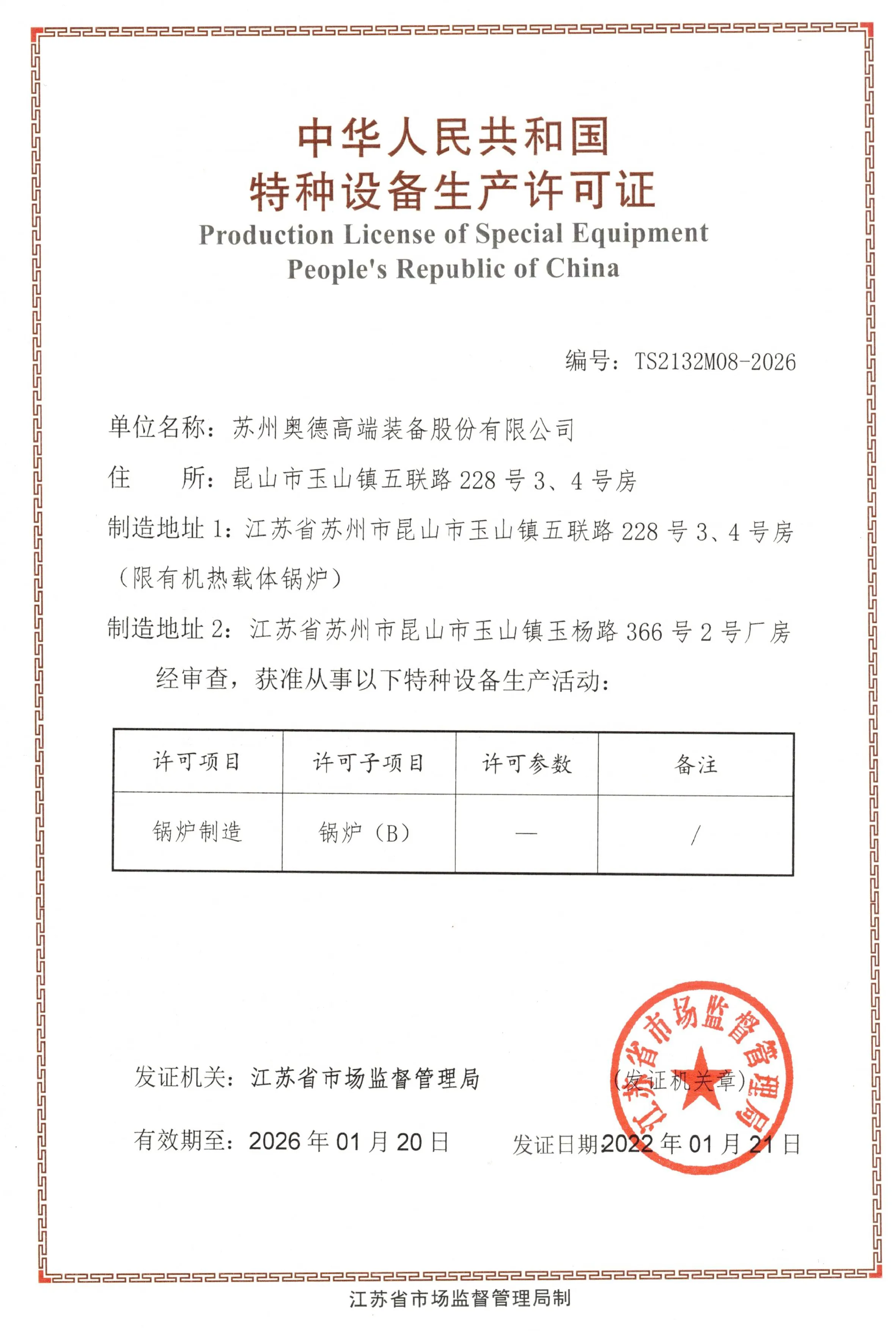

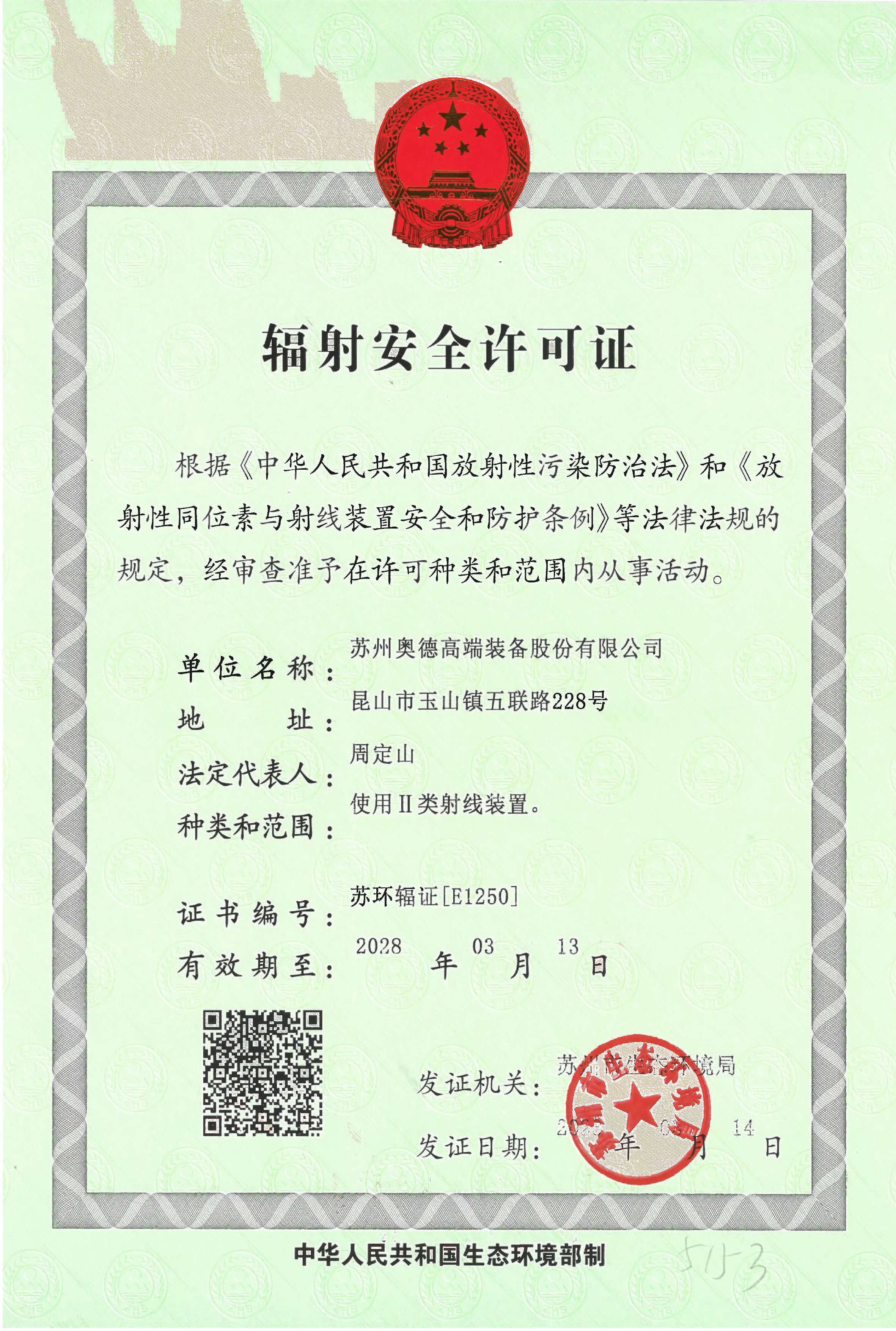

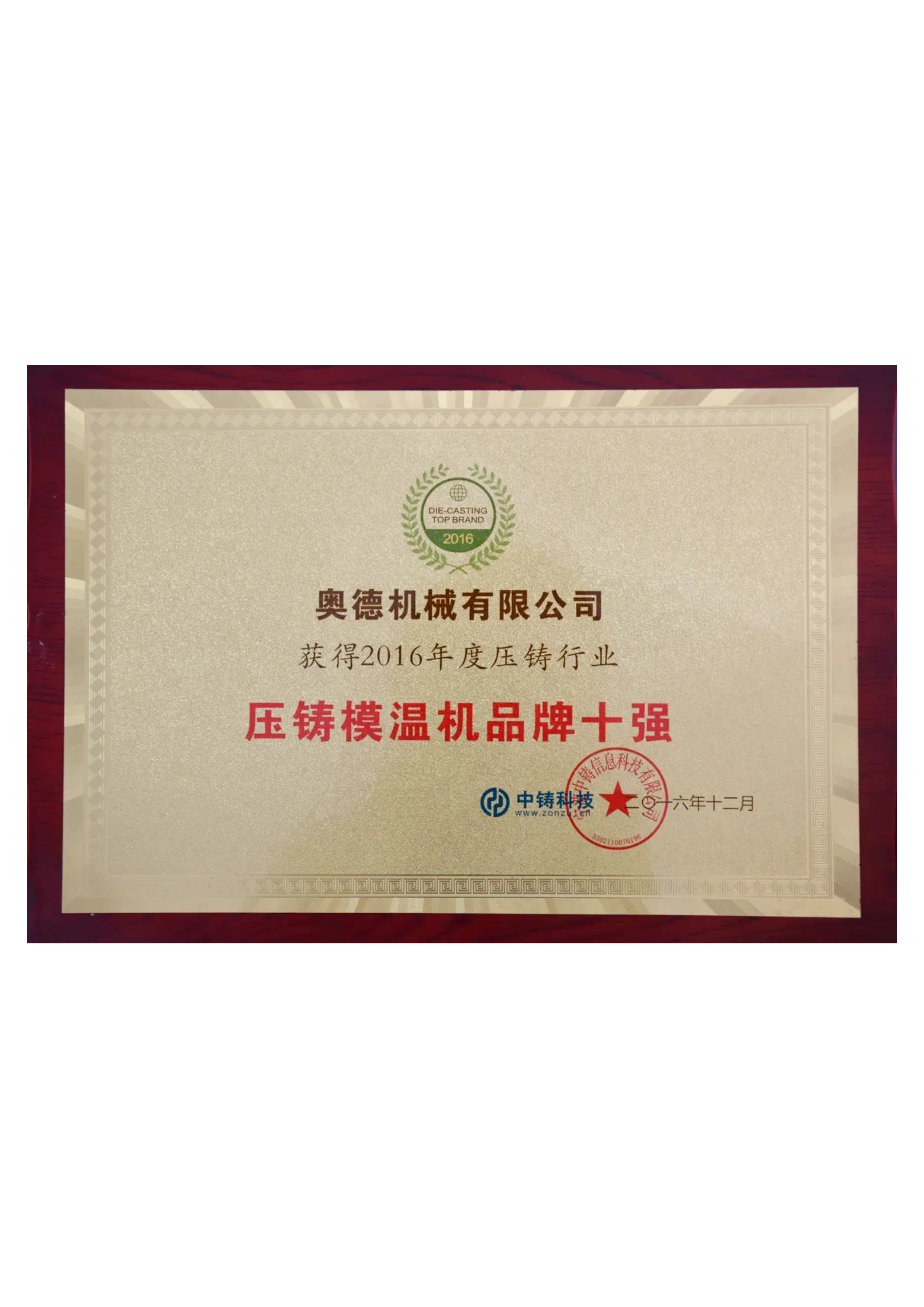

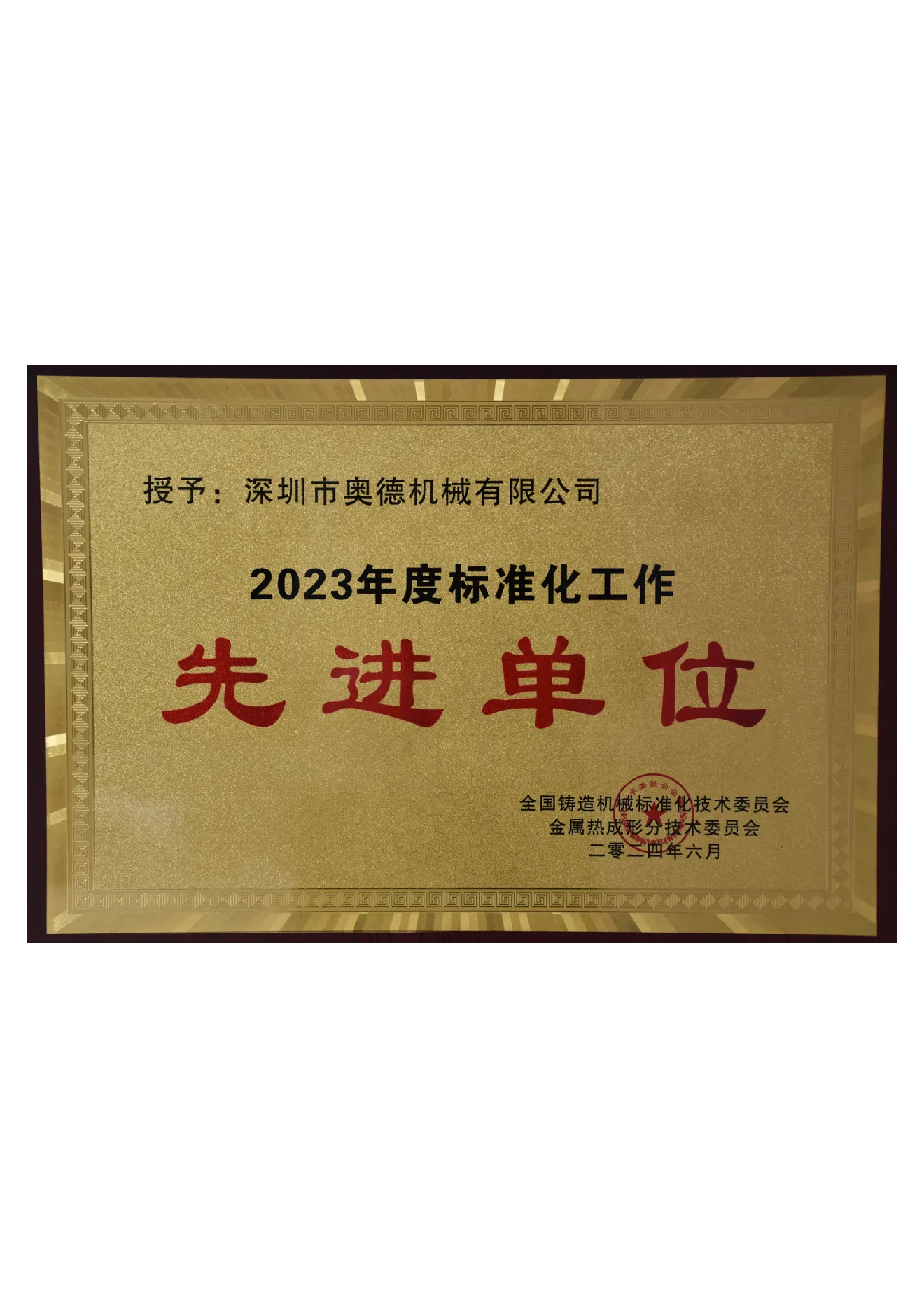

Honors and Certifications

Extensive Patent Portfolio

We hold over 306 authorized patents, covering core technologies, product design, and manufacturing processes globally.

Proven Technical Leadership

Our technology broke the dominance of European brands in high-precision optical lens manufacturing.

Technological Breakthroughs

Our R&D has yielded breakthroughs, engineering custom units for extreme temperatures with precision up to PID±0.1℃.

Our Advantages

Excellence in Manufacturing, Quality, and Support

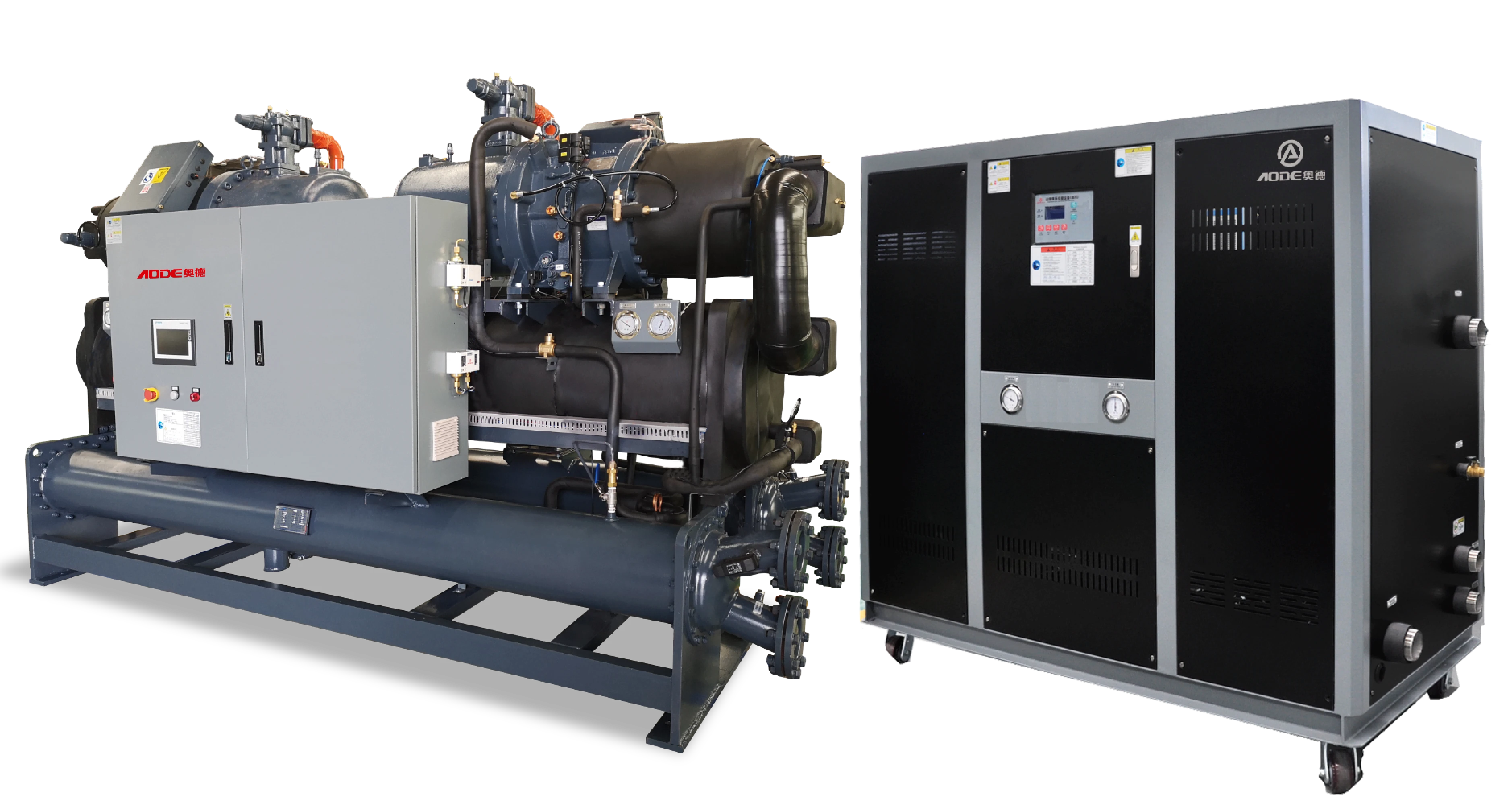

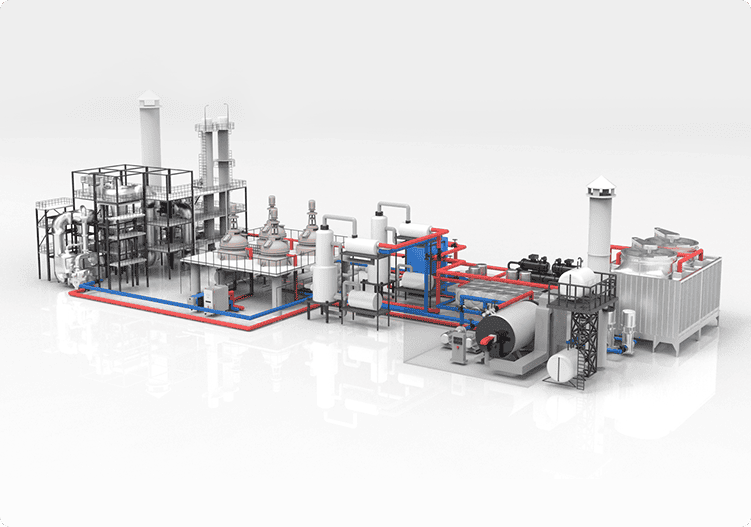

01 Precision Manufacturing

Our manufacturing strength is rooted in our expansive infra-structure. With 8 production bases spanning over 60,000 square meters, our temperature control unit factory has an annual capacity exceeding 10,000 units. This scale allows us to manage large-volume orders efficiently, ensuring the

stable supply & short lead time our international partners depend on, while maintaining the flexibility for customized solutions like chemical reactor temperature control and pharmaceutical temperature control units.

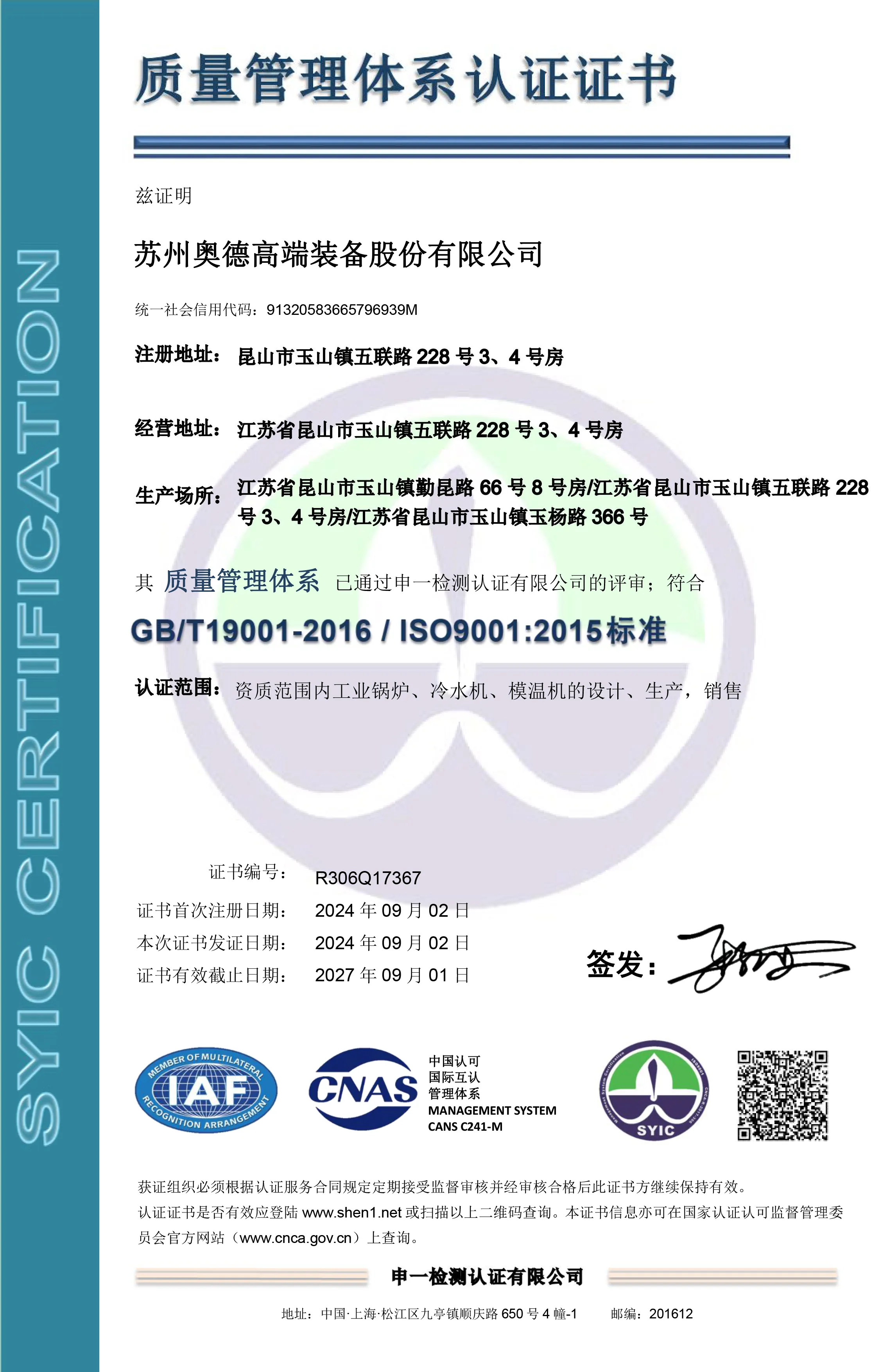

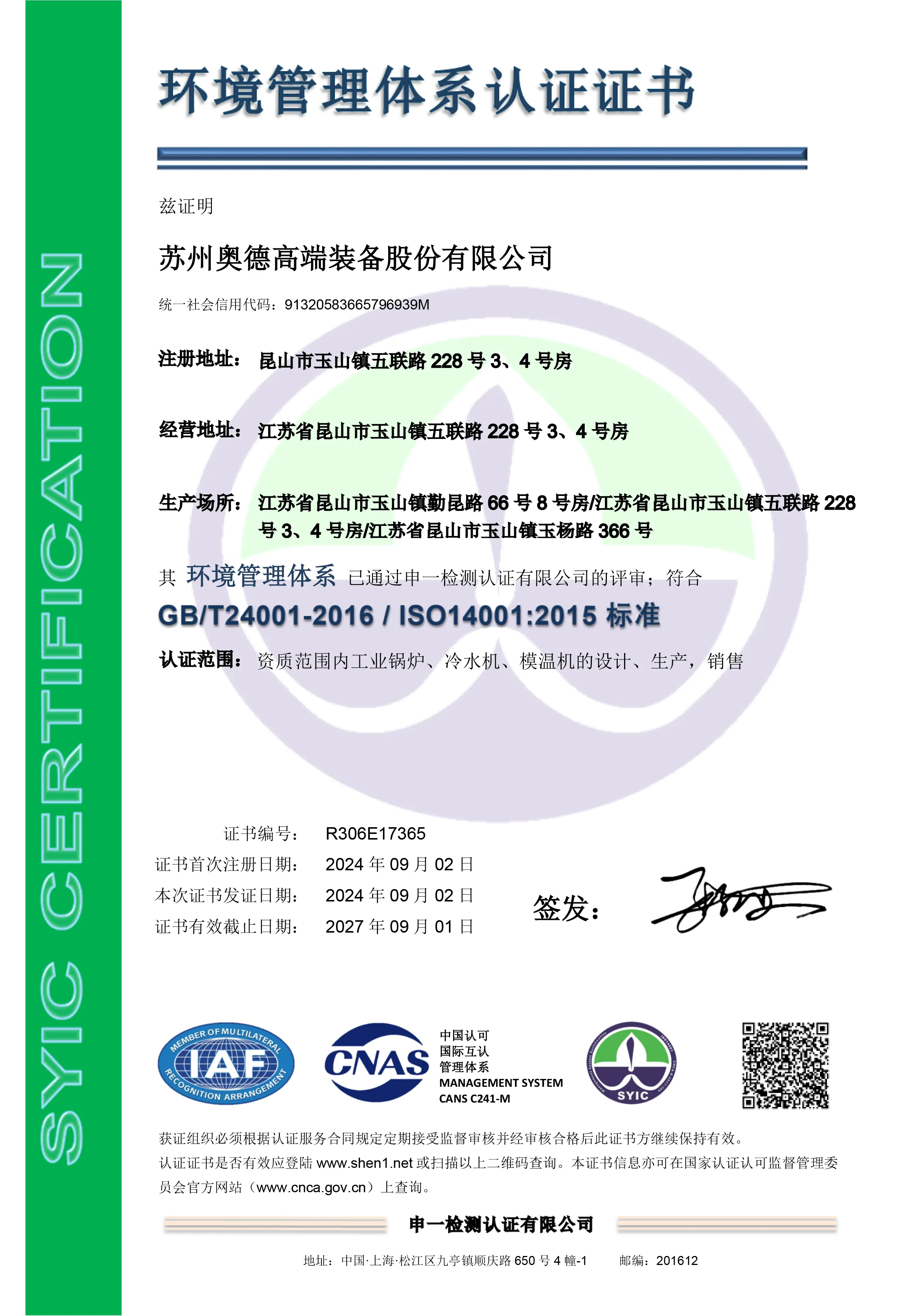

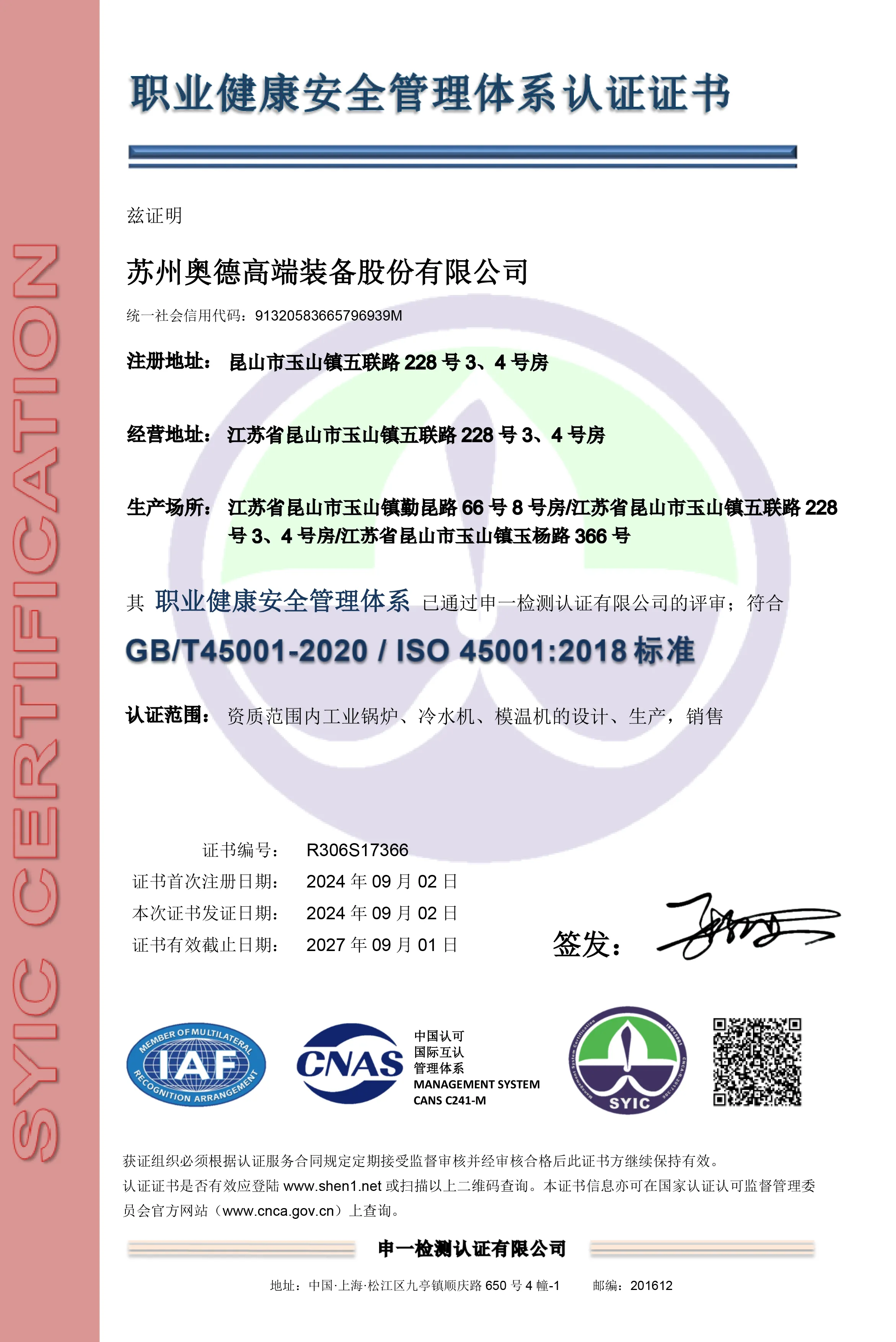

A Commitment to Global Standards and Reliable Temperature Control Systems

At AODE, our operational framework is built upon a foundation of internationally recognized management systems. These certifications are not just badges of compliance; they are a testament to our deeply ingrained culture of quality, responsibility, and continuous improvement. They provide our global partners and customers with the absolute assurance that every AODE product is manufactured to the highest global standards. Our commitment is validated by certifications for:

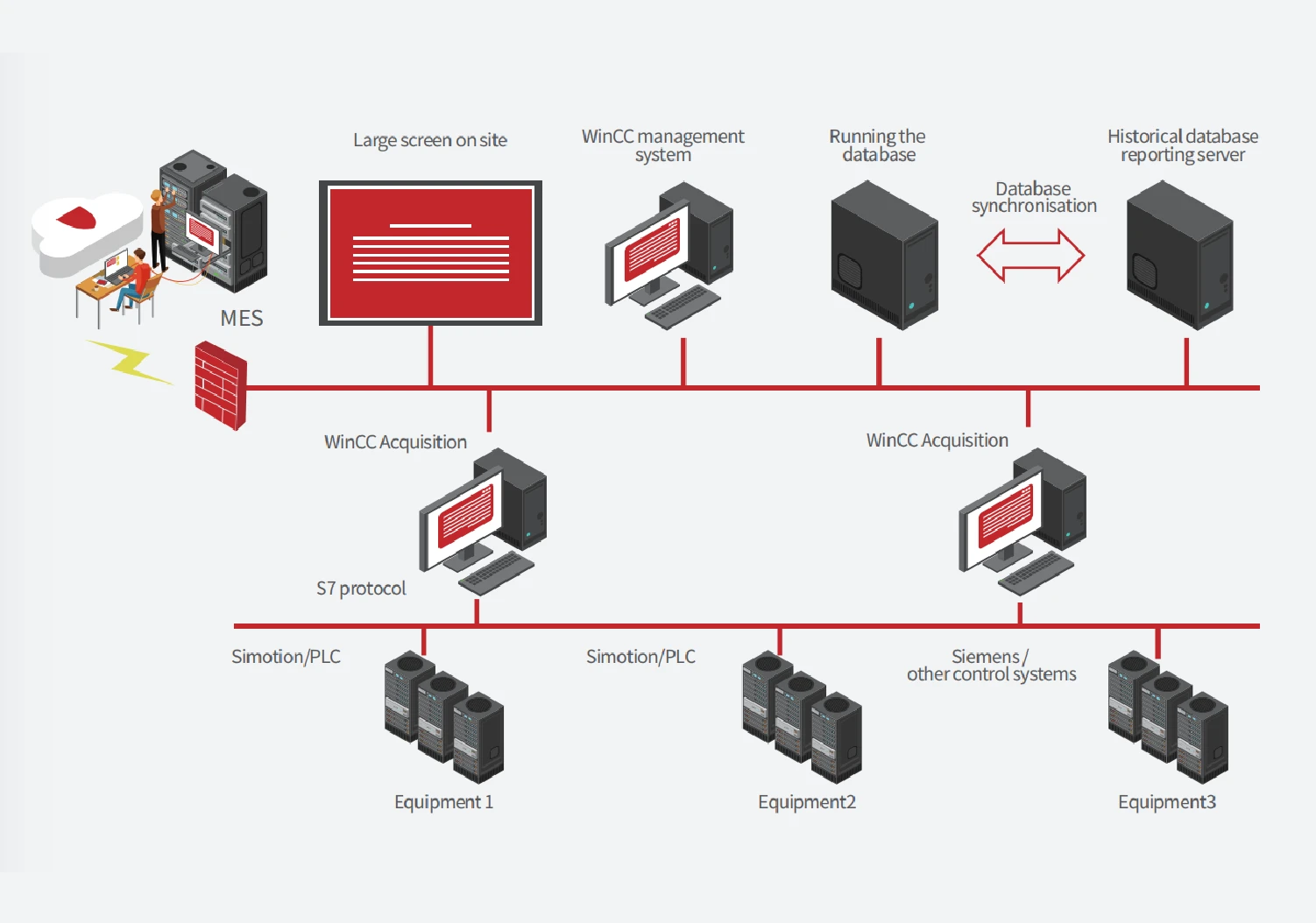

03 System Integration & DCS Control

Mold Temperature Controller Working Principle

Full Quality Control Process

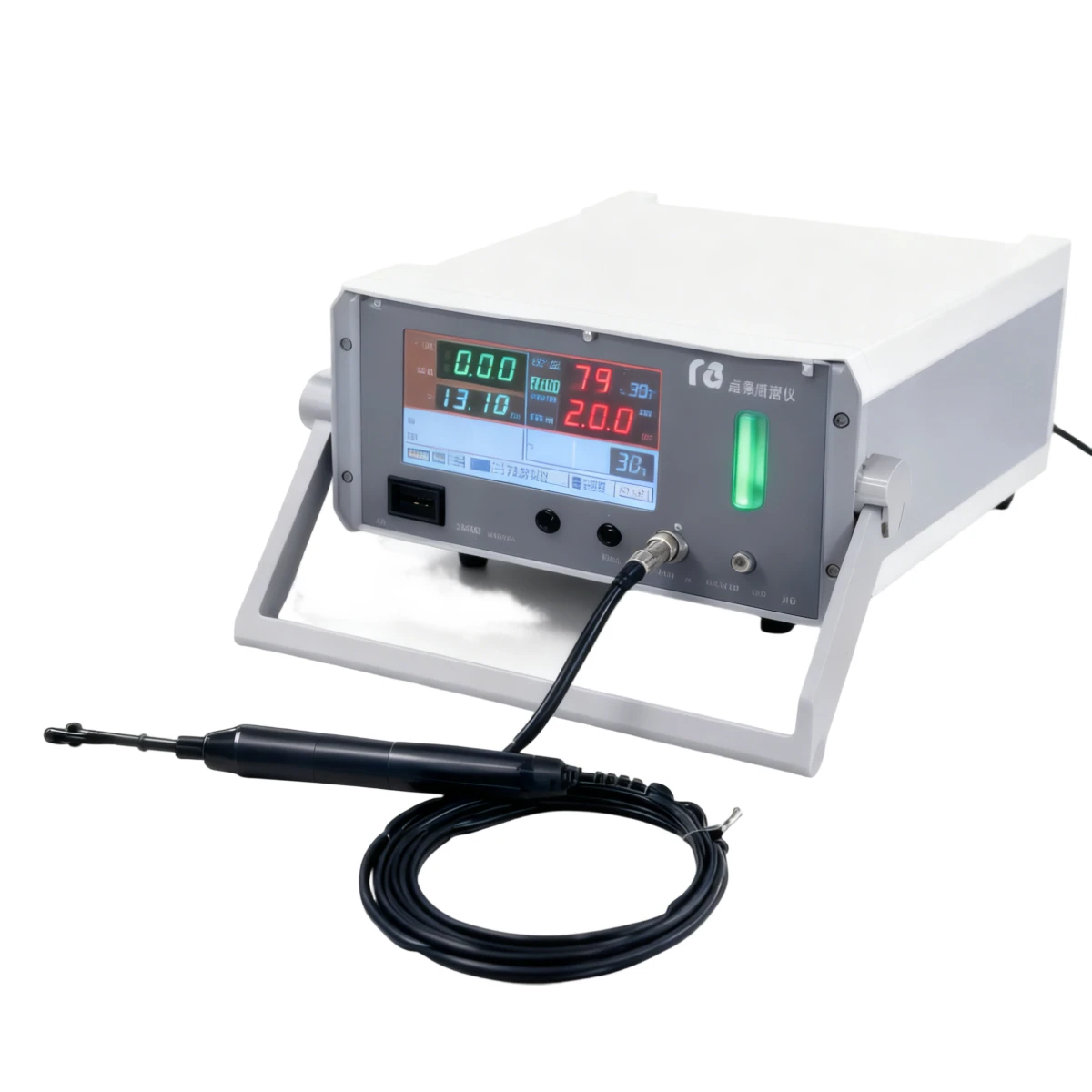

A 150+ steps quality control system spans supplier review, incoming QC, in-process control, final test and shipment checks. Our inspection toolkit covers a materials analysis spectrometer, X-ray weld inspection, helium mass spectrometer leak detection for system leak-tightness, thermal imaging, and vibration testing equipment.

Inspection Equipments Showcase

Unwavering Service & Support

Our relationship with our customers extends far beyond the sale. We have established a comprehensive service system designed to provide expert support at every stage. This includes pre-sale technical consultation to ensure optimal system selection, real-time production tracking for transparency, and a 24-hour after-sales response commitment. For our distributor network, we provide dedicated parts & training support, ensuring they have the knowledge and resources to serve their local markets effectively.