Optical-Grade Injection: ±0.1°C Water-Based Control

07 January 2026

Author:AODE

Optical-Grade Injection: ±0.1°C Water-Based Control

Process Challenges: Optical and high-end cosmetic parts demand extremely tight thermal stability; even small fluctuations can cause gloss inconsistency and dimensional deviation.

Pain Points: Conventional oil systems can be slow to respond, while common water systems may not offer the needed temperature range or precision.

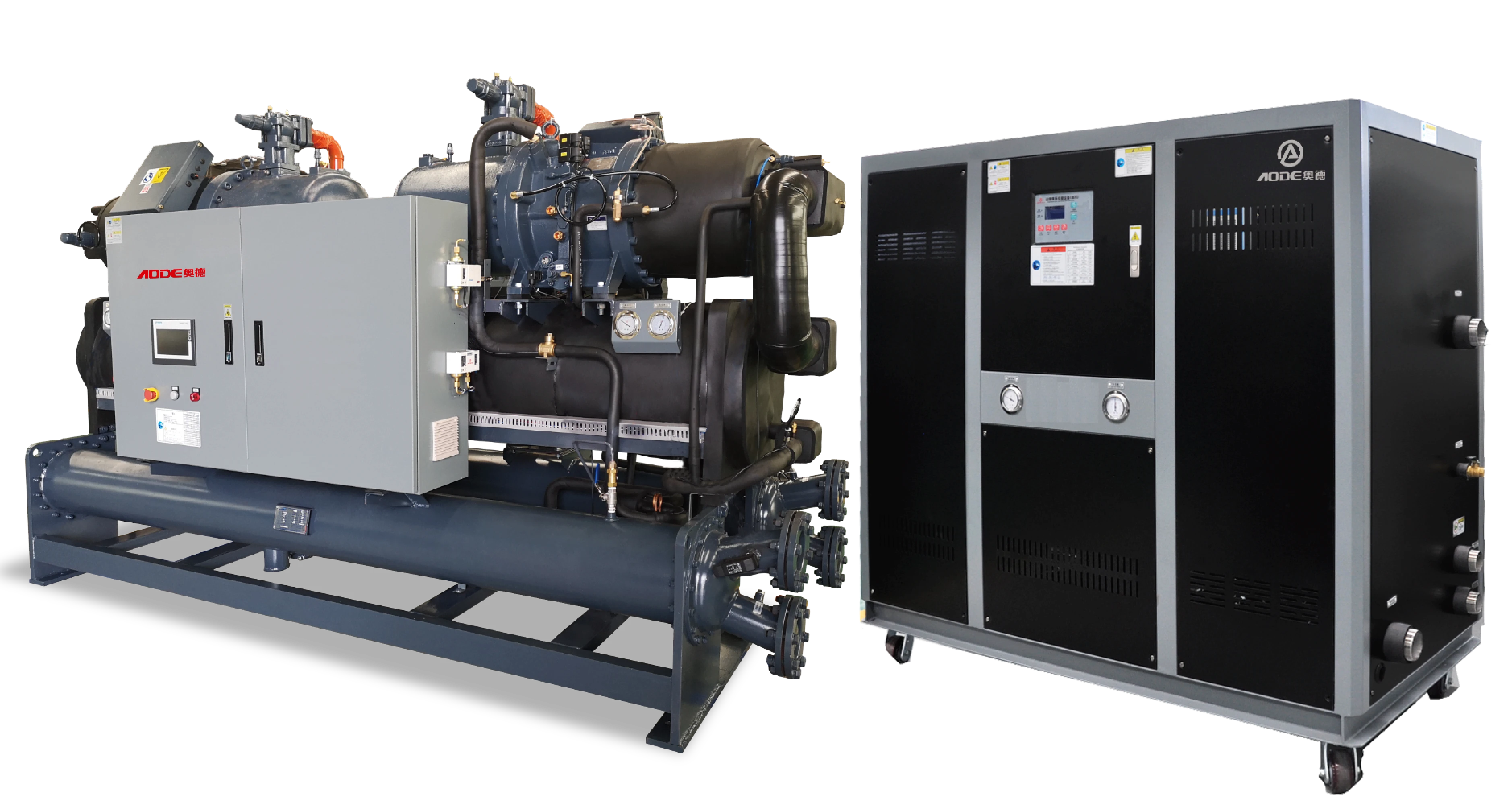

AODE Solution: AODE’s optical-grade water mold temperature controller supports +25°C to +180°C with PID ±0.1°C accuracy. Real-time monitoring of flow, pressure, and temperature improves repeatability.

Measurable Results: Customers improve finished-part yield (often referenced as 20–30% in high-gloss applications), reduce secondary finishing steps, and stabilize quality across long runs.

Back to List

Back to List

Table of Contents

Related Cases

High-Gloss / Paint-Free Parts: Rapid Hot–Cold Molding