High-Gloss / Paint-Free Parts: Rapid Hot–Cold Molding

07 January 2026

Author:AODE

High-Gloss / Paint-Free Parts: Rapid Hot–Cold Molding

Process Challenges: Appearance parts are easily affected by weld lines, flow marks, and silver streaks when mold temperature drifts.

Pain Points: Scrap and rework rise quickly; operators must constantly tweak settings, and cycle time is often limited by cooling.

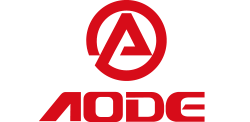

AODE Solution: AODE applies rapid hot–cold mold temperature control—fast heating to the target mold temperature for filling, then rapid switching to cooling after packing/holding. Dual-PID control reduces overshoot and stabilizes every cycle.

Measurable Results: Customers typically report fewer surface defects, more consistent gloss, and shorter cycles—supporting higher throughput on appearance-critical programs.

Back to List

Back to List

Previous

No more

Next

Optical-Grade Injection: ±0.1°C Water-Based Contro...

Table of Contents

Related Cases

Optical-Grade Injection: ±0.1°C Water-Based Control