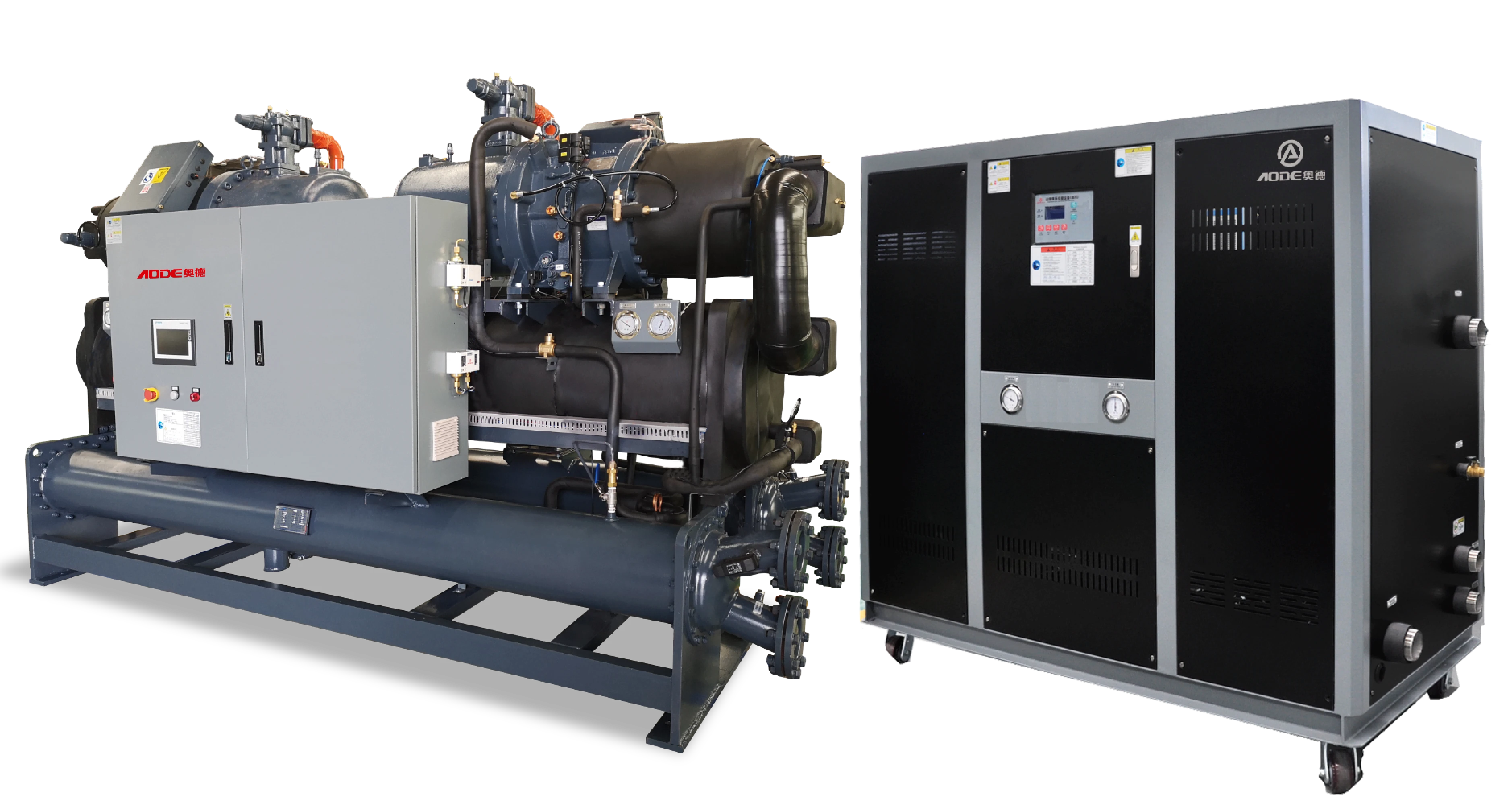

Die Casting Special Multi-channel High Temperature Water TCU

+25℃  +180℃

+180℃

Single, double circuit design, each machine can simultaneously docking 10-40 mold channels

Each branch can choose intermittent water control, and the temperature control interval is effectively extended.

Optional independent display of each branch flow, temperature, pressure and other monitoring parameters.

Effectively reduce the number of die-casting water temperature machine configuration.

Reduce the installed power of the die-casting island and the requirements for public works.

Save space, reduce equipment investment and pipeline installation costs.

Product Specifications

| ITEM | UNIT | WT95D-150T-72 | WT180D-30T/2-12 |

| Temp control range | ℃ | Inlet water temperature+25℃~95℃ | Inlet water temperature+25℃~180℃ |

| Temp control accuracy | ℃ | PID±1 | |

| Power supply | / | AC 3N-380V/400V50HZ | |

| Heat transfer medium | / | Water | |

| Coolingmethod | / | Indirect Cooling | |

| Number of mould runners available | / | 40-channel | 12-channel (dual-loop design) |

| Coolingpower | KW | 580kW@95℃/380kW@80℃ | 350KW+350KW @180℃ |

| Heating capacity | KW | 72 | 30+30 |

| Motor power | KW | 11 | 4+4 |

| Pumpflow | L/min | 450 | Maximum Flow 200L/min |

| Pump head | m | 85 | Maximum Head 90m |

| Max.power consumption | KW | 85 | 71 |

| Alarm function | / | Pump reversal/Water shortage/Overheating/Overloading/High pressure/pressure divergence/flow divergence | |

| System function | / | Each channel independently controls and displays flow,pressure,temperature and other parameters | |

| Circulating water pipe | inch | 2" | Internal Thread G1.5"*2 |

| Coolingwaterpipe | inch | 2" | Internal Thread G1.5" |

| Size(L×W×H) | mm | Main Unit:1300*900*1000 Distribution Box:600*500*1200 | Main Unit:1500mm*620mm*1550mm Distribution Box:500mm*530mm*630mm |