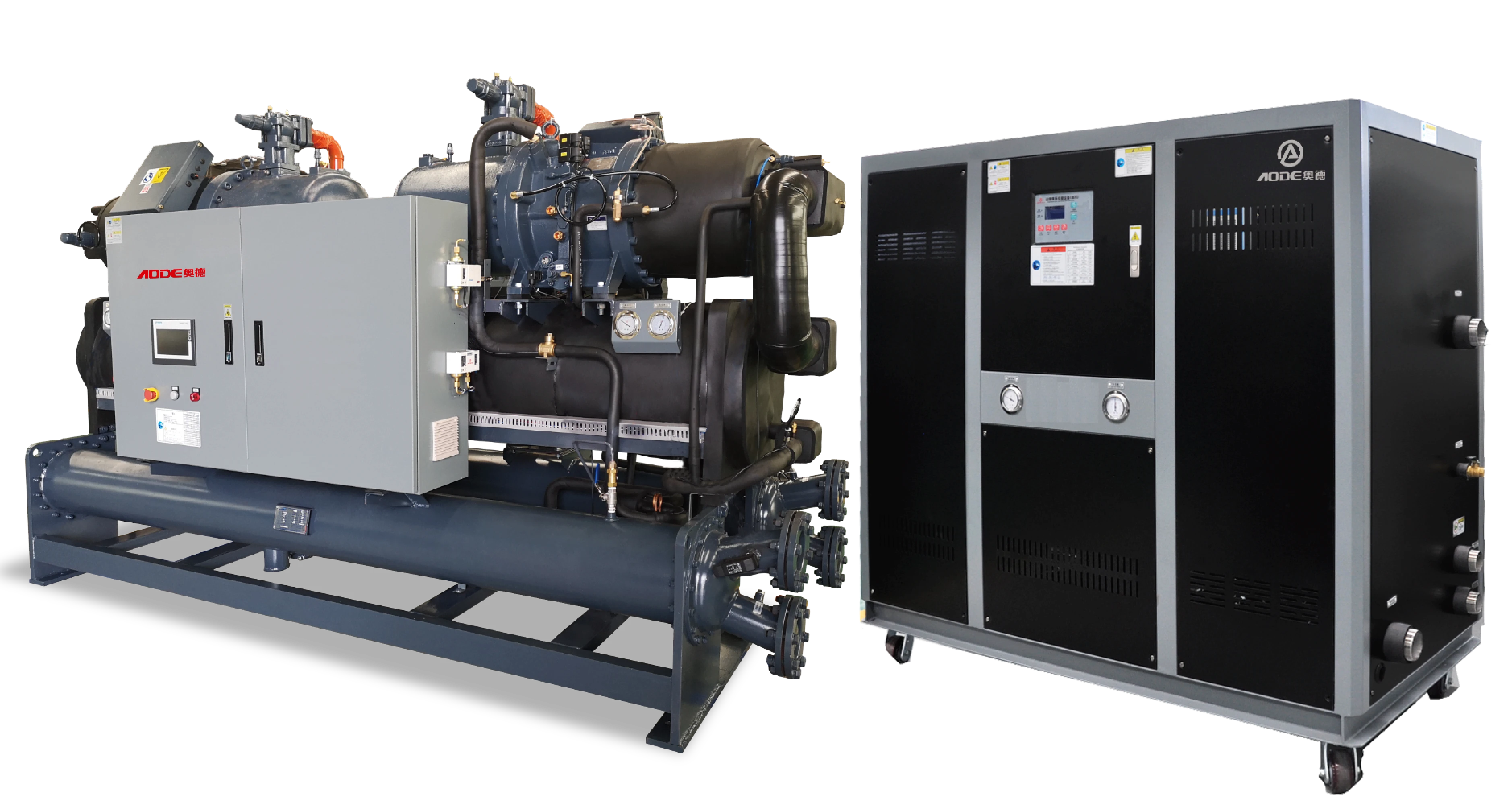

Oil Temperature Control Unit For Die Casting

+45℃  +320℃

+320℃

Single or dual loop is optional to realize partition control

Preheat/cool, mold heat balance

Improve product appearance

Defective product reduction

Prolong die life

To achieve uniform spraying and micro

Product Specifications

| ITEM | UNIT | Normal form | Lot type | Normal form | Lot type | Normal form | Lot type | Normal form | Lot type |

| ADDC-36 | OT320D-24 | ADDC-48 | OT320D-30 | ADDM-36 | OT320D-24/2 | ADDM-48 | OT320D-30/2 | ||

| Temp controlrange | ℃ | Inlet water temperature+45℃~320℃ | |||||||

| Temp controlaccuracy | ℃ | PID±1 | |||||||

| Powersupply | / | AC3N-380V/400V-50HZ | |||||||

| Heattransfer medium | / | Thermo conductive oil | |||||||

| Coolingmethod | / | Indirect Cooling | |||||||

| Cooling capacity | m | 3/8 | 3/8 | 1/2 | 1/2 | 0.36+0.36 | 0.48+0.48 | 0.48+0.48 | 0.48+0.48 |

| Expansion tank | L | 40 | 40 | 67 | 67 | 62 | 62 | 62 | 62 |

| Heating capacity | KW | 15*2 | 12*2 | 20*2 | 15*2 | 30+30 | 24+24 | 40+40 | 30+30 |

| Motor power | KW | 1.1 | 1.1 | 3 | 3 | 1.1+1.1 | 3+3 | 3+3 | 3+3 |

| Pumpflow | L/min | 30 | 30 | 75 | 75 | 30+30 | 75+75 | 75+75 | 75+75 |

| Max.power consumption | KW | 31 | 25 | 43 | 33 | 62 | 54 | 86 | 66 |

| Alarm function | / | Pump reversal/Oil shortage/Overheating/Overload/Abnormal heating | |||||||

| Coolingwaterpipe | inch | 1/2 | 1/2 | 3/4*2 | 3/4*2 | ||||

| Circulating oil pipe | inch | 3/4 | 1 | 3/4*2 | 1*2 | ||||

| Size(L×W×H) | mm | 1400*500*1150 | 1650*550*1250 | 1380*600*1400 | 1380*600*1400 | ||||