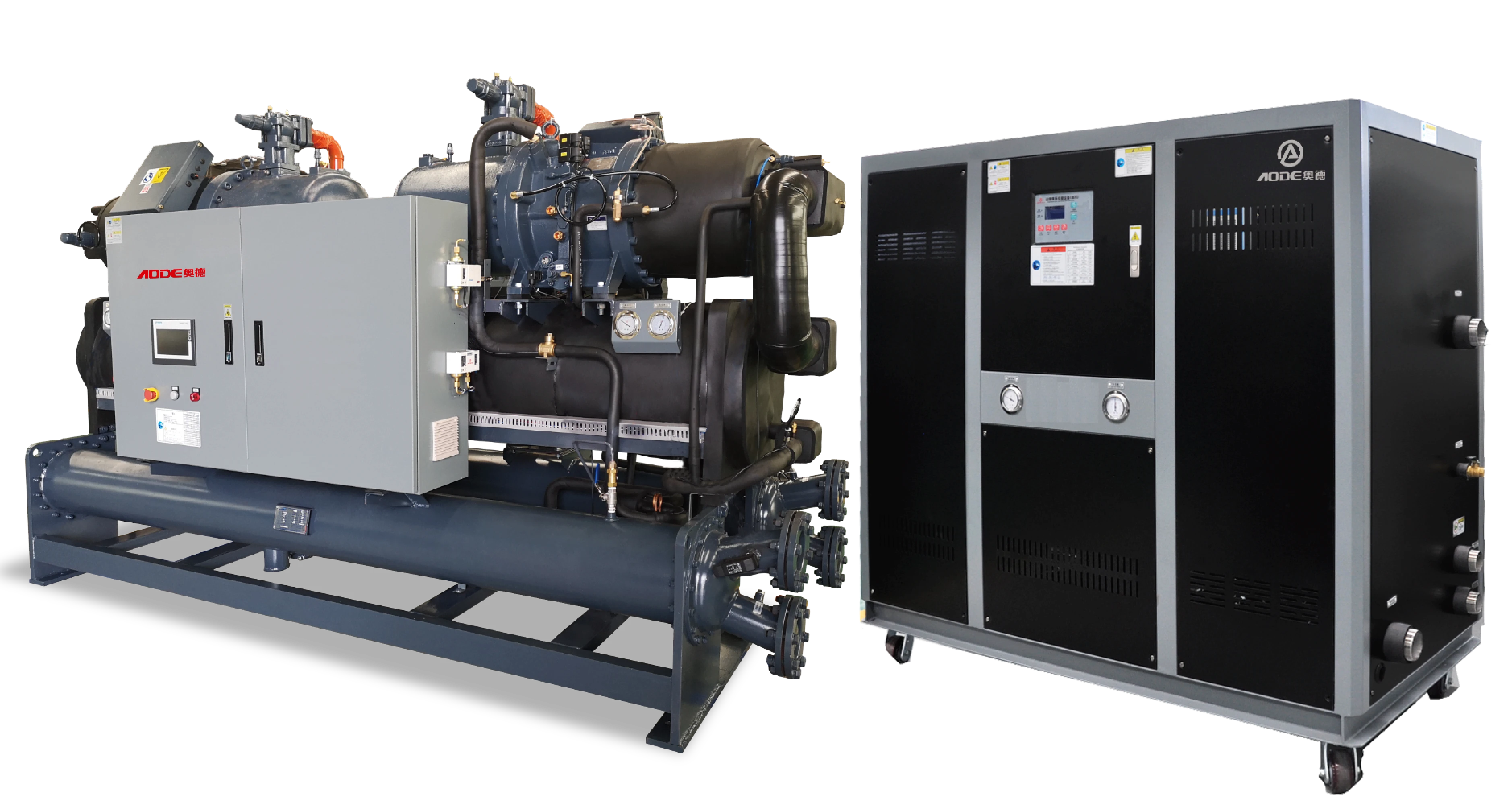

Electrically Heated Organic Heat Transfer Fluid System

+45℃  +400℃

+400℃

Explosion-proof device、Blow-up oil return function (optional)

RS485 communication function for automation management

Isolated electrical control box to prolong the use of electrical appliances

Pipeline using organic heat carrier furnace special pipeline

Perfect safety protection, fault display, maintenance, repair and maintenance of no need for professionals

Product Specifications

| ITEM | UNIT | YWDR0.12- 0.5/300/280 | YWDR0.24- 0.5/300/280 | YWDR0.3- 0.5/300/280 | YWDR0.6- 0.5/300/280 | YWDR1.0- 0.5/300/280 | YWDR1.5- 0.5/300/280 |

| Temp control accuracy | ℃ | PID±1℃ | |||||

| Power supply | / | 3PAC380V/480V 50HZ(3phase+Earth) | |||||

| Heat transfer medium | / | Thermal conductive oil | |||||

| Rated power | KW | 120 | 240 | 300 | 600 | 1000 | 1500 |

| Thermal efficiency | % | 98 | 98 | 98 | 98 | 98 | 98 |

| Design pressure | Mpa | 0.75 | 0.75 | 0.75 | 0.75 | 0.75 | 0.75 |

| Motor power | KW | 5.5 | 11.0 | 11.0*2 | 22.0*2 | 37.0*2 | 45.0*2 |

| Pump flow | m³/h | 34 | 50 | 50 | 100 | 160 | 200 |

| Pump head | m | 40 | 50 | 50 | 55 | 50 | 53 |

| Max. power consumption | KW | 127.5 | 251 | 322 | 622 | 1037 | 1545 |

| Alarm function | / | Pump reversal/Oil shortage/Overheating/Overload/Abnormal heating/Pressure to protect | |||||

| Connecting pipe size | inch | 2" | 3” | 3" | 4 " | 6” | 8” |

| Size(L×W×H) | mm | 2450*800*1900 | 2520*900*2100 | 2600*1000*2170 | 2800*1300*3000 | 3000*2200*3500 | 4200*3000*3800 |