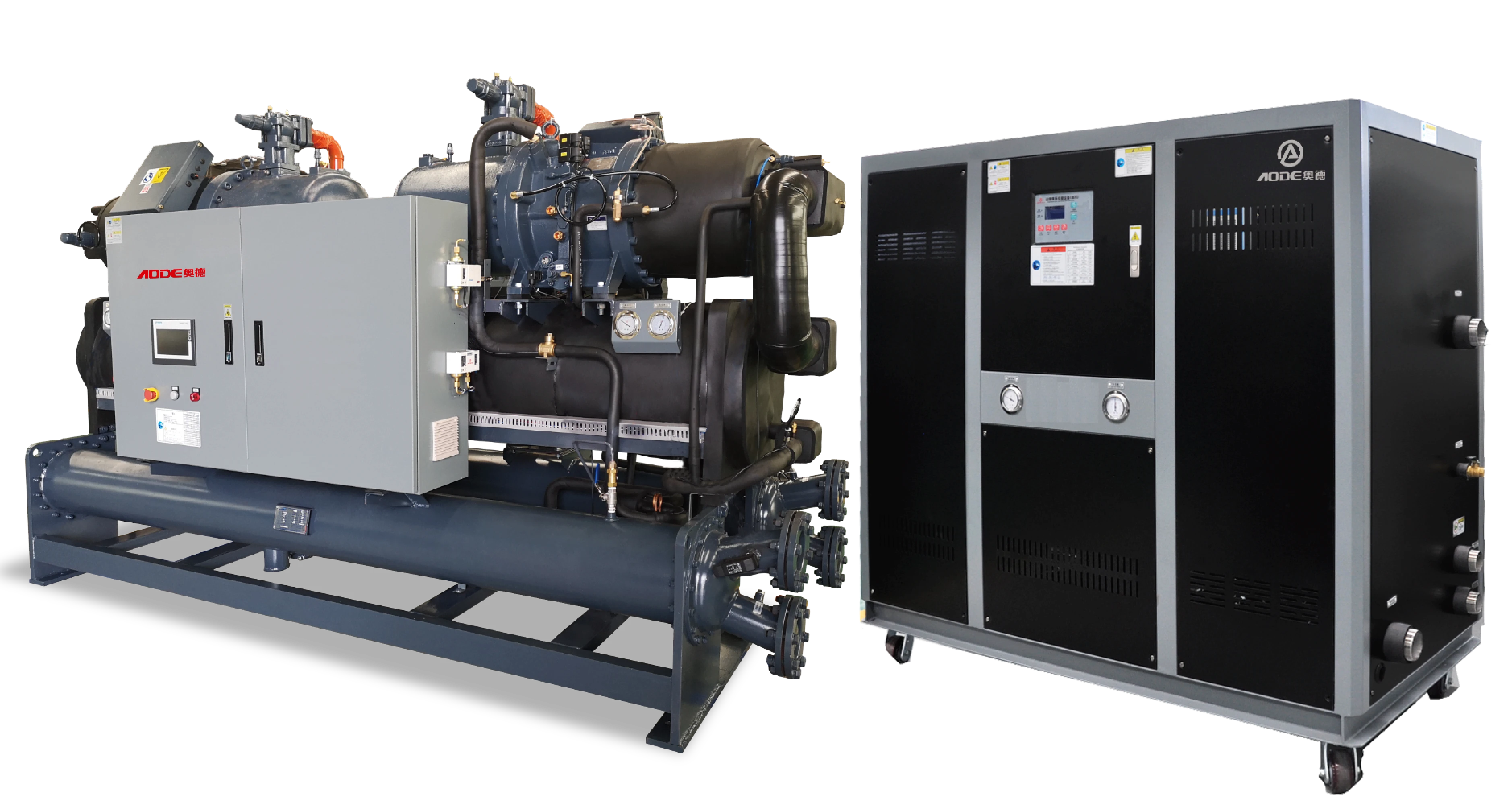

BWS High-gloss Steam Mold Temperature Control Unit

+25℃  +180℃

+180℃

Eliminate soluble wiring, melted marks, corrugated, silver marks on the product surface.

Completely solve surface shrinkage of plastic products.

Improve the surface gloss, the surface roughness is similar to mirror.

Products do not need to spray paint processing, improve the rate of finished products of 20-30%.

Solve the fiber products floating fiber problem, make the product quality perfect.

The thin-wall molding can improve the liquidity of injection, improve product quality and intensity

Thick-wall injection molding cycle can be reduced by 60%, increase the liquidity and fill effects of the plastic

Condensation,heat release,quicken the speed of heat exchanger,enhance the heating rate Without connecting boilers and other external thermostat auxiliary equipment,omitted the complex boiler equipment (high-pressure equipment safety and Environmental approval) and Pipeline Project.

Completely solve the problem of the boiler steam non-recyclable.

Small volume can match different machines, 180 ℃ hot water can replace the boiler, which is not Environmental

Product Specifications

| ITEM | UNIT | BWS-600 | BWS-800 | BWS-1600 |

| Power supply | V/Hz | AC3N-380/400V-50Hz | ||

| Total power | kw | 65 | 106 | 157 |

| Total current | A | 100 | 160 | 236 |

| Control mode | / | PLC & Human-Machine Interface (HMI) | ||

| Maximum water consumption | kg | 70 | 125 | 184 |

| Saturated steam temperature | ℃ | 182 | ||

| Water filling pump power | kw | 0.75 | ||

| Cooling pump power | kw | 1.5 | 2.2 | 4 |

| Cold/hot water circulation outlet and inlet dimension | inch | 1 or 3/8 (6 outlet 6 inlet) | 1-1/4 or 3/8 (10 outlet 10 inlet) | 1-1/2 or 3/8 (14 outlet 14 inlet) |

| Cooling water inlet dimension | inch | 1-1/4 | 1-1/2 | 2 |

| Compressed air inlet diameter | inch | 1/2 | 1/2 | 1/2 |

| Size (L×W×H) | mm | 1450*700*1350 | 1750*900*1350 | 1950*950*1550 |