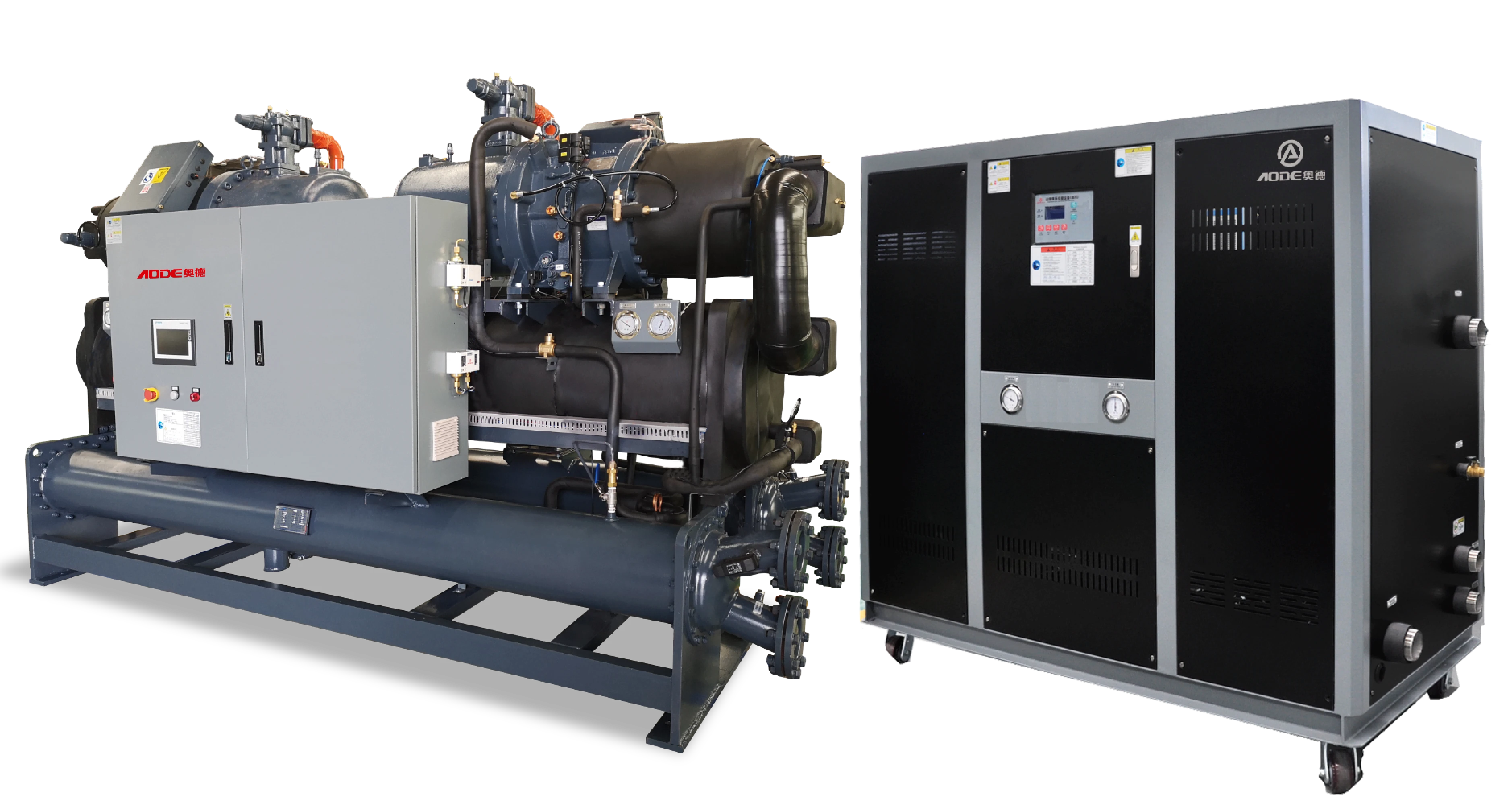

Organic Heat Transfer Material Heater

+25℃  +300℃

+300℃

No oil collection plate, no dead angle of the flow of heat medium oil, but also to prevent the oil collection plate high pressure to produce the risk of oil leakage breakage.

Front and rear doors can be opened quickly to provide quick inspection and maintenance.

With a fire view window, you can clearly monitor the combustion condition. With explosion-proof ports,to prevent the furnace ignition and deflagration in time to relieve the pressure,other boilers generally do not have this device.

Three-layer boiler shell insulation, the inner ceramic fibre,the middle rock wool boards,the outer lightweight cement, in order to reduce the loss of accumulation and improve the strength of the outer shell

Three-circuit tube coil design, heat transfer area than the general thermal media boiler on the market of about 30%,in order to reduce the exhaust gas temperature and greatly improve the efficiency of the boiler.

Large combustion chamber,to avoid flame contact with the tube wall and damage,and reduce NOx emissions.

Product Specifications

| ITEM | UNIT | YY(Q)W-1800Y、Q | YY(Q)W-2400Y、Q | YY(Q)W-3000Y、Q | YY(Q)W-3500Y、Q | YY(Q)W-4000Y、Q | YY(Q)W-4600Y、Q | YY(Q)W-6000Y、Q | YY(Q)W-7000Y、Q | YY(Q)W-8200Y、Q | YY(Q)W-9300Y、Q | YY(Q)W-12000Y、Q | YY(Q)W-14000Y、Q |

| Rated Thermal Power | kcal/h | 150*10⁴ | 200*10⁴ | 250*10⁴ | 300*10⁴ | 350*10⁴ | 400*10⁴ | 500*10⁴ | 600*10⁴ | 700*10⁴ | 800*10⁴ | 1000*10⁴ | 1200*10⁴ |

| KW | 1800 | 2400 | 3000 | 3500 | 4000 | 4600 | 6000 | 7000 | 8200 | 9300 | 12000 | 14000 | |

| Thermal Efficency | % | 92 | |||||||||||

| Design Pressure | MPa | 0.8 | |||||||||||

| Design Temperature | ℃ | 300/350/380 | |||||||||||

| Oil Capacity Inside Furnace | m³ | 1.7 | 2.0 | 2.54 | 2.9 | 3.6 | 4.1 | 4.9 | 5.6 | 8 | 9 | 11.2 | 12.3 |

| PumpPower | KW | 30 | 37 | 45 | 55 | 55 | 75 | 90 | 130 | 75*2 | 75*2 | 90*2 | 90*2 |

| Pumpflow | m³h | 132 | 176 | 220 | 256 | 293 | 337 | 418 | 406 | 250*2 | 300*2 | 400*2 | 450*2 |

| Pumphead | m | 56 | 55 | 55 | 55 | 52 | 60 | 56 | 56 | 56 | 56 | 53 | 53 |

| Connecting Pipe Size | mm | 125 | 150 | 150 | 200 | 200 | 200 | 250 | 250 | 300 | 300 | 300 | 350 |

| Max.power consumption | KW | 40 | 50 | 62 | 72 | 72 | 95 | 115 | 170 | 195 | 200 | 235 | 250 |

| Gas Consumption | m³/h | 190 | 253 | 316 | 379 | 442 | 506 | 632 | 758 | 885 | 1011 | 1264 | 1517 |

| Oil Consumption | kg/h | 160 | 213 | 266 | 320 | 373 | 426 | 533 | 639 | 746 | 853 | 1066 | 1279 |